Comprehensive guide: Installation, commissioning and maintenance of organic fertilizer fermentation composting machines

Organic Fertilizer fermentation composting machine plays a vital role in Organic Fertilizer Production Line. This article will provide you with a comprehensive installation, commissioning and maintenance guide to ensure efficient operation and extended service life of the equipment.

Installation and commissioning:

- Check the equipment foundation and power supply: Before installing the organic fertilizer fermentation compost converter, we must first ensure that the equipment foundation is stable and the power line is safe and reliable. This is essential to ensure the stability and safety of equipment operation.

- Operation test of the Turning mechanism: taking the Windrow Compost Turning Machine as an example, the installation should check whether the running of the turning mechanism is smooth and whether the turning depth is uniform, which directly affects the fermentation effect of organic fertilizer.

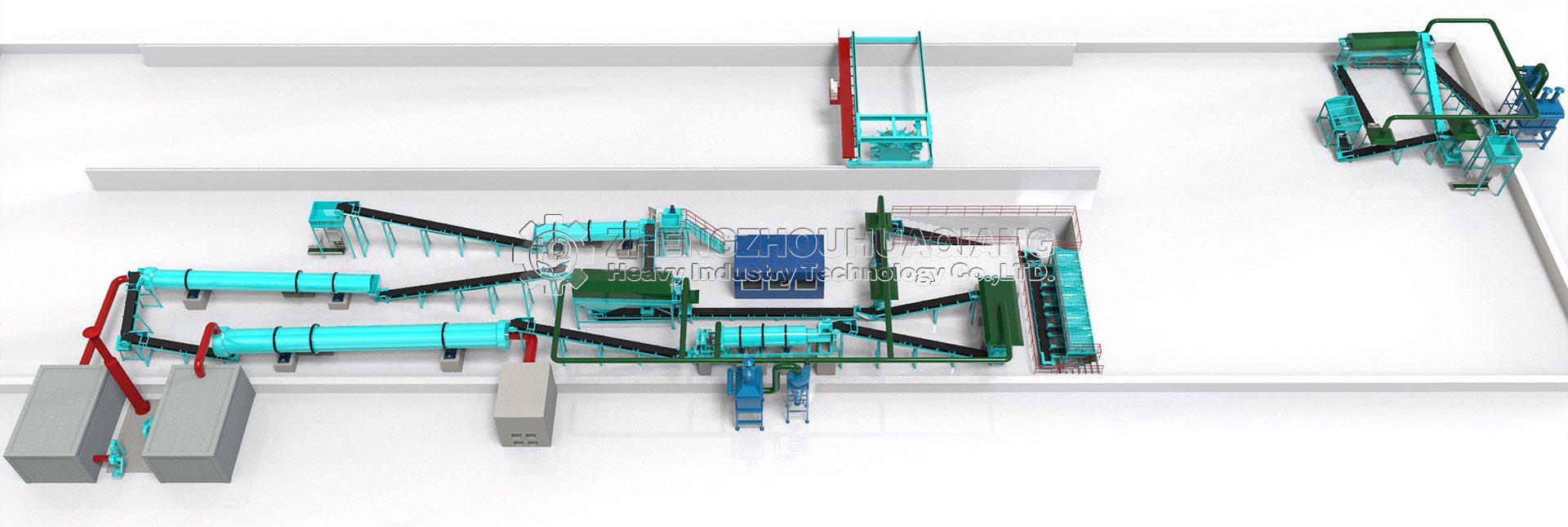

- Granulation equipment adjustment: The rear end of the Organic Fertilizer Production Line is usually configured with Rotary Drum Granulator or Disc Granulator. When installing the organic fertilizer production line, ensure that the gap between the mold and the press roll is moderate to ensure the uniformity and strength of particles.

- Mixing and Screening equipment inspection: Fertilizer mixers (such as Horizontal Ribbon Mixer) and screening machines (such as Rotary Screening Machine) in the production line should check the wear of mixing blades and screens to ensure uniform mixing and screening effect.

- Installation of supporting equipment: Uniform Feeder installation and debugging is equally important, it can ensure that raw materials are continuously and evenly fed into the fermentation or granulation equipment, improve production efficiency.

Maintenance:

- Daily inspection and fastening: Every 10 hours or so, check and tighten the connection bolts and nuts to ensure that the oil drain plug is not loose.

- Inspection of vulnerable parts: Regularly check the wear of latches, cotter pins and tilting knives, and replace new parts or tighten bolts if necessary.

- Cleaning and rust prevention: regularly clean the bonded attachments on the equipment, and apply oil to prevent rust when not used for a long time, and cover protection when outdoor storage.

- Lubrication and replacement of grease: After working for a season, replace the gear oil of the reducer, clean and apply new butter to all parts of the bearing.

- Electrical equipment maintenance: Check the electrical control system to ensure that the line connection is intact, the electrical components are not damaged, and the equipment is well grounded.

- Safety device inspection: Regularly check the safety device of the equipment to ensure its sensitivity and reliability.

- Record and analysis: Establish equipment usage records, including inspection, repair, maintenance and other historical records, in order to master the equipment status.

- Special season maintenance: Add antifreeze when using in winter, use warm water to operate, and drain the water in the tank, body and cooler after operation.

- Belt maintenance: Regularly check the tension of the drive belt and adjust or replace the belt if necessary.

By following these meticulous installation, commissioning and maintenance steps, you can ensure the efficient operation of the organic fertilizer fermentation composting machine, but also extend the service life of the equipment, and provide stable equipment support for the production of organic fertilizer.