How does organic fertilizer fermentation equipment work in agricultural waste treatment?

In modern agriculture, the disposal of agricultural waste has always been an important issue. Through organic fertilizer fermentation equipment, these wastes can be converted into valuable fertilizer resources. So, how exactly do these devices work?

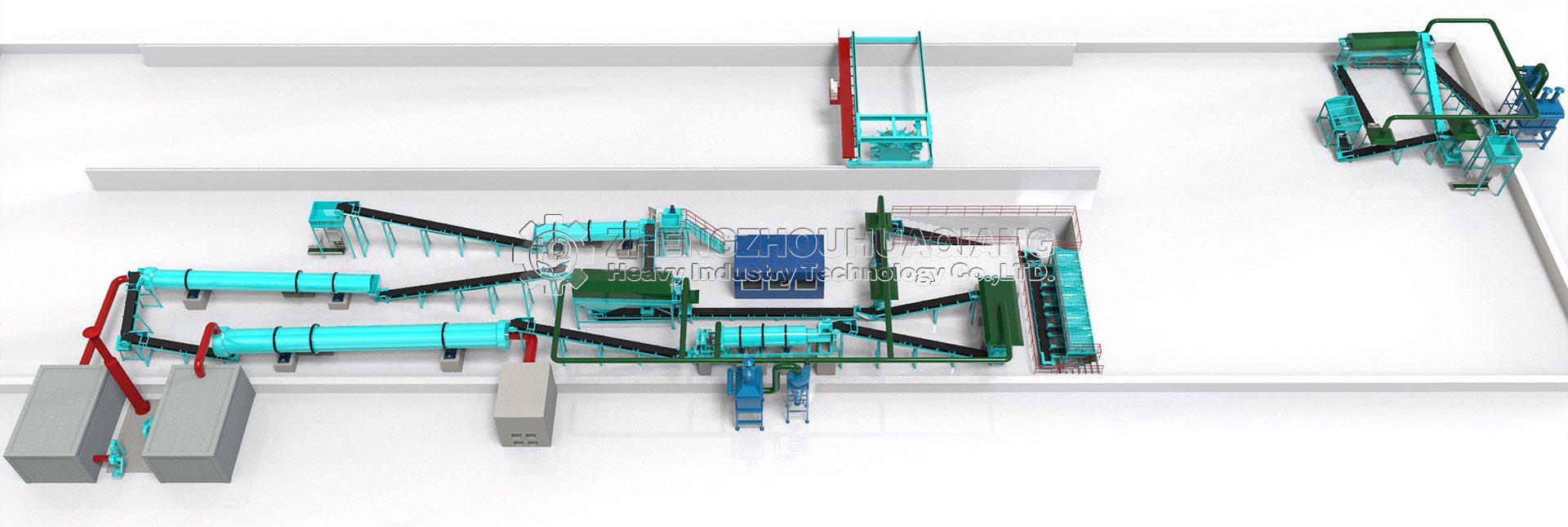

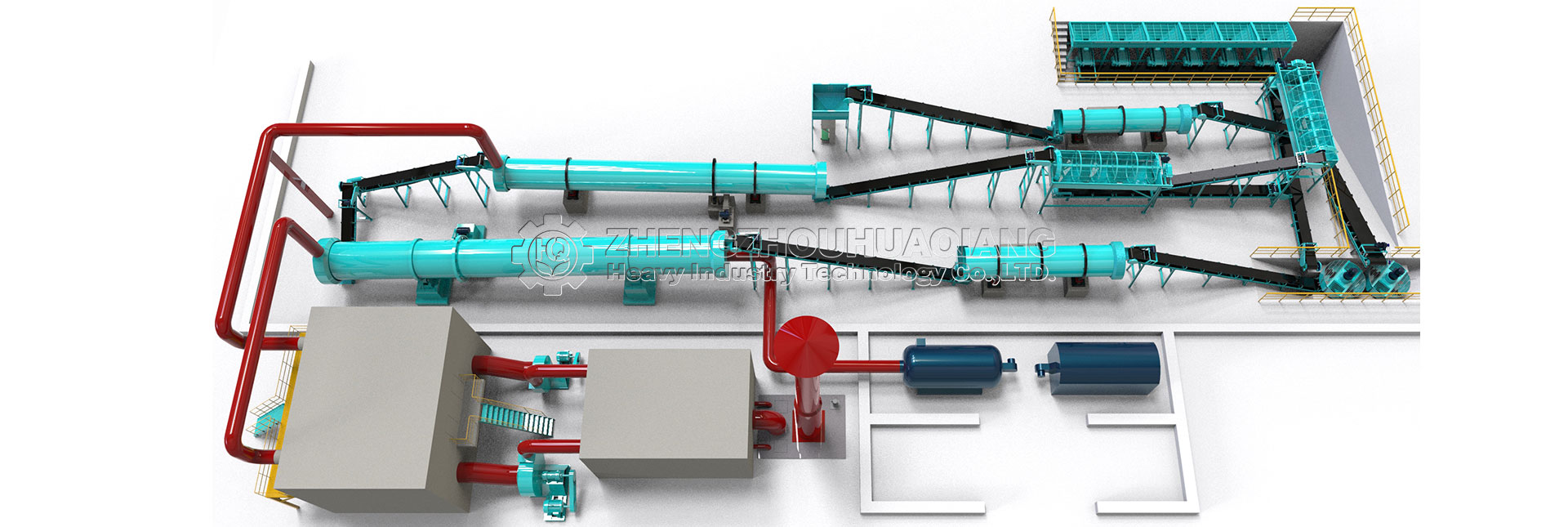

First of all, agricultural waste such as crop straw, livestock manure, etc., after preliminary collection and classification, is sent into the Organic Fertilizer Production Line. This production line usually includes crushing, mixing, fermentation and other steps. Fertilizer shredders such as Cage Crusher and Compost Crusher play a key role in breaking waste to the right size for subsequent processing.

Next, the crushed material enters the mixing stage. Horizontal Ribbon Mixer or Double Shafts Paddles Mixer mixes the waste with the right amount of microbial inoculant to prepare the fermentation process. The mixture is then fed into the Compost fermentation area, where the Windrow Compost Turning Machine regularly turns the pile to ensure adequate oxygen, promote microbial activity and speed up the fermentation process.

After fermentation is complete, the material enters the Fertilizer Granulating Production Line. Here, depending on your needs, you can choose between a Fertilizer Granules Compaction Machine, a Flat-Die Pellet Machine, Rotary Drum Granulato, or a Disc Granulator. Through different working principles, these granulators make the fermented material into granular organic fertilizer, which is easy to store and apply. If it is necessary to produce nitrogen, phosphorus and potassium composite fertilizers, appropriate amounts of nitrogen, phosphorus and potassium can be added before granulation to form NPK Fertilizer Production Line.

Finally, the organic fertilizer after granulation needs to go through the steps of screening, drying and cooling. Fertilizer screeners ensure uniform particle size, while Rotary Dryer machines and Rotary Cooler machines remove excess water and reduce temperature, respectively, so that the final product meets quality standards.

In the whole process, Uniform Feeder ensures the stable flow of materials between all links, improving production efficiency. Through these advanced organic fertilizer fermentation equipment and production lines, agricultural waste can be efficiently converted, not only to solve the problem of environmental pollution, but also to provide high-quality organic fertilizers for agricultural production, to achieve resource recycling and sustainable development.