To build a new fertilizer plant, many factors need to be considered in advance, and pre-research and preparation should be made, so that difficulties will not be heavy after implementation.

1. Organic fertilizer plant size and site selection

The scale of the plant is not only related to the funds you are going to invest, but also the local fertilizer demand. Big factories have higher relative productivity and low consumption. Meanwhile, do?the preliminary?market?research. You need consider the fertilizer demand in the next 5-10 years, fertilizer varieties needed by farmers.

Site selection is a very important part

a. Organic fertilizer plant can not be too far from the breeding plant. Chicken manure, pig manure, cow manure, duck manure and other animal manure from breeding plants are large in volume, high in water content and inconvenient to transport. If they are too far away, the transportation cost of organic fertilizer plants is too high.

b. Organic fertilizer plant can not be too close to the breeding plant, and can not be in the wind direction of the breeding plant. Otherwise, it is easy to infect diseases, which will bring difficulties to breeding plants.

c. Stay away from residential areas. Organic fertilizer plants can produce odorous gases in production, which can not be in residential living and working areas, nor can it be in the trend of residential area.

2.Selection of organic fertilizer raw material

a. Botanical raw materials

Plant straw: Corn stalk, wheat straw, rice straw, bean stalk, banana skin, peanut skin, etc.

b. Animal material

Animal wastes: Chicken manure, duck manure, sheep manure, cow dung, pig manure.

Animal processing waste: Animal viscera

c. Other raw materials

Plant ash, tephros, silt, etc.

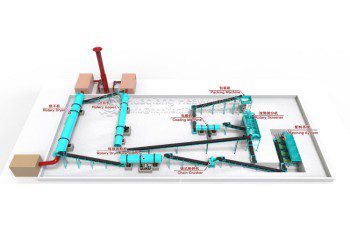

3.Production process of oranic fertilizer

A complete set of main equipment for organic fertilizer production line:

a. Processing equipment:

Compost turning machine: Turn the raw materials to compost, and shorten compost time.

Livestock manure dewatering machine

b. Crushing equipment: Crush the compost material to small powder, and ready to granulator.

Half-wet material crusher, Chain crusher, Cage crusher, Straw crusher

Horizontal mixer, Vertical disc mixer, Double axis mixer, BB fertilizer blender

d. Granulation equipment: The fertilizer granulator processing powder into granules.

Organic fertilizer granulator, Ring die granulator, roller press granulator, two in one organic fertilizer granulator

e. Drying equipment and Cooling equipment: After granulating, the moisture of fertilizer is a bit high, it’s not suitable for long-term storage so need drying process.

Drum fertilizer dryer, Drum fertilizer cooler

f. Screening equipment: screen appropriate granules and prepare for packaging.

Drum screener machine, Vibration screeener machine

g. Coating machine

h. Packing equipment

Belt conveyor, Bucket elevator, Screw conveyor, Large angle belt conveyor

Finally, how can we choose the right equipment for organic fertilizer production? Zhengzhou Tianci Co., Ltd.warmly give the following suggestions:

1. When choosing and purchasing organic fertilizer equipment, try to choose a regular old-brand enterprise. It can effectively reduce the risk of strength, quality and follow-up service. 2. Before purchasing organic fertilizer equipment, we must communicate our actual situation and plans with the staff clearly, so that the enterprise can provide you with the most feasible plan.