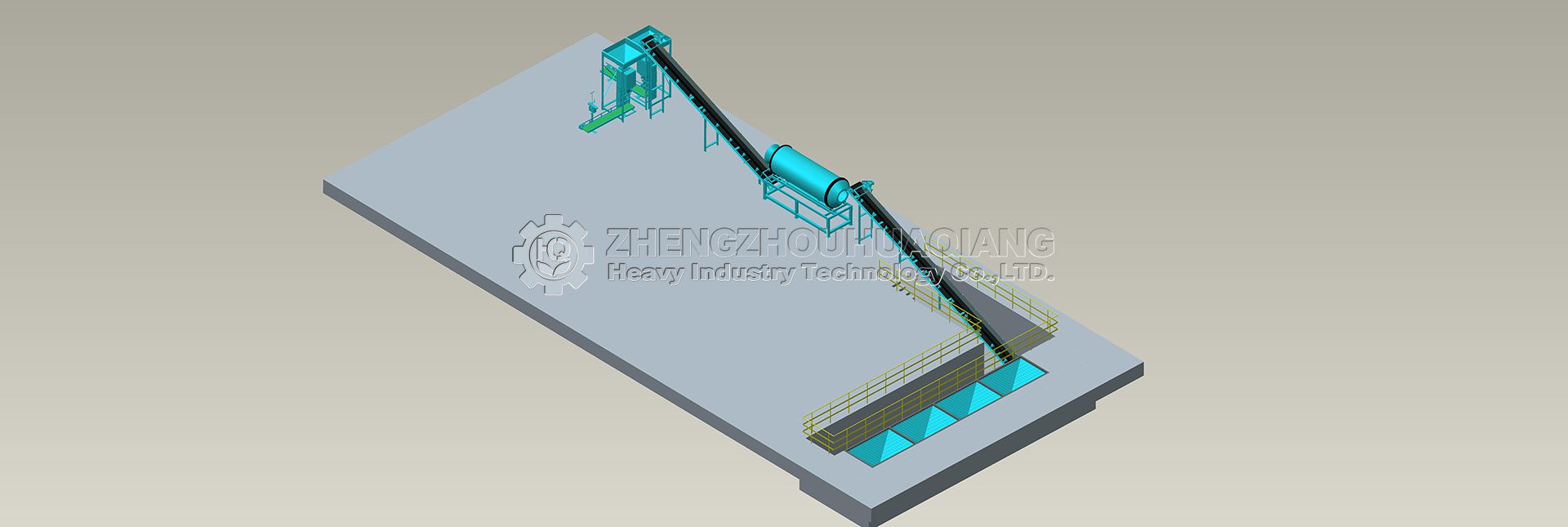

NPK blending fertilizer production line is designed and manufactured according to the requirements of compound fertilizer plant and fertilizer distributor, and its productivity is 10000 – 100000 tons. The feeding of lifting tank and loading of material by mixer almost reach zero waste.

NPK Blending Fertilizer Production Line

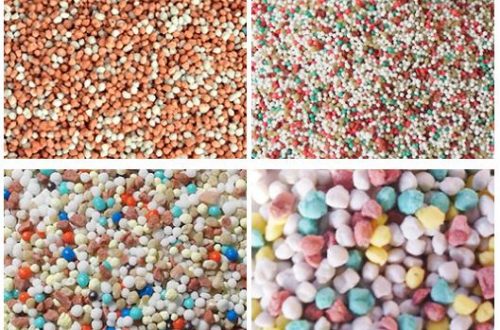

Material: Any two or three chemical fertilizers containing three nutrient elements, nitrogen, phosphorus and potassium

Motor Power: 4-5t/h

Major Equipment: batching system, belt conveyor, bb fertilizer mixer, packing machine and so on

Major Equipment

Project Details

NPK blending fertilizer production line is designed and manufactured according to the requirements of compound fertilizer plant and fertilizer distributor, and its productivity is 10000 – 100000 tons. The feeding of lifting tank and loading of material by mixer almost reach zero waste. The main body of NPK blending fertilizer mixer adopts the forward or reverse movement mode, and adopts the built-in screw structure and three-dimensional structure to mix conveying materials.

NPK blending fertilizer production line is mainly composed of batching system, belt conveyor, bulk blending fertilizer mixer and packaging machine.

Batching system: The automatic batching system is mainly composed of feeding system, weighing device, silo and conveyor belt. And the static batching system has both the speed of Dynamic Batching and the accuracy of ordinary static batching (0.2%).

Belt Conveyor: Mobile lifting belt conveyor is the same as ordinary belt conveyor in working principle. It takes belt as the continuous conveying equipment of traction bearing machine. Compared with ordinary belt conveyor, it adds mobile device and lifting device. Because there are more lifting and moving devices, mobile lifting belt conveyor has increased its superior dynamic capacity, which can be realized by now. The site conditions are propelled or towed by forklift and other power locomotives to the appropriate location for loading and unloading.

Bulk blending fertilizer mixer: This series of NPK blending fertilizer equipment is a new generation of mixing equipment developed by our company. Its outstanding advantages are large mixing volume, easy formulation and strong pertinence. It overcomes the diversion phenomenon caused by the mixture flowing downward due to the difference of material specific gravity and particle size, and improves the proportioning accuracy. Moreover, the product is simple in structure, easy to operate, easy to maintain, greatly reducing equipment investment, thereby saving human, financial and energy consumption.

Packaging machine: automatic packaging scale, also known as automatic packaging machine, can be divided into semi-automatic packaging scale and fully automatic packaging scale. The packaging scale mainly consists of automatic quantitative packaging scale (consisting of storage hopper, feeder, weighing and clamping hopper, kneading mechanism, computer control, pneumatic execution part, etc.) and selection part (conveyor, sewing machine/heat closing machine). Using spiral feeding, the material is forcibly discharged by feeding mechanism.

Advantages of NPK blending fertilizer production line:

1. The single bag mixing method is easy to control the material of each bag, and the mixing uniformity is high.

2. The spiral section of the mixing section is designed reasonably and uniquely, the mixing is even, and the material can enter and leave quickly.

3. Computer automatic batching/mixing/packaging, using twisting cage feeding method, occupies a small area, less labor and less investment.

4. The whole equipment is made of stainless steel with corrosion resistance and long service life.

Features of NPK blending fertilizer production machine:

1. Suitable for uniform mixing of various solid powders

2. Granular raw materials should not be crushed during mixing

3. Productivity is 4-5 t/h

4. Material mixing uniformity meets technical requirements

5. Small environmental pollution, meeting environmental requirements

6. The overall layout is beautiful, compact and easy to operate and maintain.

7. The equipment has low cost and good technical and economic performance.

Project Video

Our Services

Process flow design

We provide you with the pro-phase plan, process flow design and manufacturer equipment according to your special demand.

Sale and Installation

Delivery the machines on time and send technicians to the job-site for guiding the installation and adjustment, training operators and finishing the check and accept.

Plant planning

According to the factory, to make a design about the equipment place, to divide the area of production.

After-sales service

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, spares and the after sale service.