When choosing organic fertilizer equipment, how to judge the quality and performance of the equipment?

Organic fertilizer is an indispensable part of modern agricultural production, and the efficient operation of its production line is directly related to the quality of fertilizer and the yield of crops. Therefore, it is crucial to choose high-quality organic fertilizer equipment. This article will provide you with some key metrics to help you judge the performance of organic fertilizer equipment.

1. Equipment material and manufacturing process

The material and manufacturing process of organic fertilizer production line are important criteria to judge its quality. High-quality equipment usually uses wear-resistant and corrosion-resistant materials, such as stainless steel, to ensure the durability and stability of the equipment. At the same time, the sophisticated manufacturing process can ensure the precise fit of the equipment and the reliability of long-term operation.

2. The technical level of the equipment

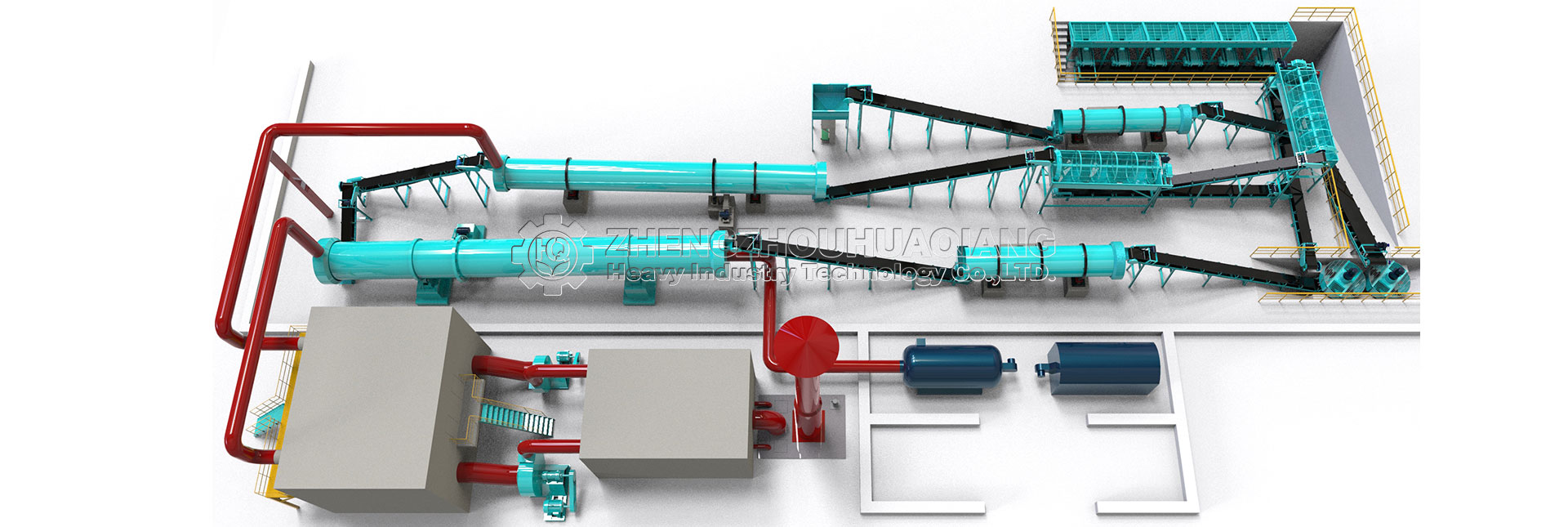

Technical level is the key to measure the performance of organic fertilizer equipment. Modern organic Fertilizer Production lines, such as the NPK Fertilizer Production Line, should have automated control, accurate metering and efficient material handling capabilities. The application of these technologies can significantly improve production efficiency and product quality.

3. The stability and reliability of the equipment

The stability and reliability of organic fertilizer production line are important factors affecting its performance. For example, the Rotary Drum Granulator in the organic fertilizer production line should be able to operate continuously and stably to ensure the continuity and uniformity of production. The failure rate of the equipment is low, and the maintenance is simple and convenient, which are important indicators to judge the performance of the equipment.

4.Energy consumption and environmental performance

With the improvement of environmental awareness, the energy consumption and environmental performance of organic fertilizer equipment have also been paid more and more attention. High-quality organic fertilizer equipment should have good energy-saving performance and environmental protection effects, such as the Rotary Dryer Machine in the organic fertilizer production line should adopt energy-saving design to reduce energy consumption, and the noise and exhaust gas generated during the operation of the equipment should meet environmental protection standards.

5. After-sales service and technical support

Good after-sales service and technical support is an important guarantee to ensure the long-term stable operation of organic fertilizer equipment. When selecting equipment, consider the manufacturer’s after-sales service network, availability of spare parts, and technical support capabilities.

6. Field visits and user feedback

Before purchasing organic fertilizer equipment, it is best to investigate the operation of the equipment on the spot to understand the actual performance of the equipment and the ease of operation. At the same time, the evaluation and feedback of other users can be referred to a more comprehensive understanding of the quality and performance of the equipment.

Through the comprehensive consideration of the above aspects, you can more accurately judge the quality and performance of organic fertilizer equipment, so as to make a wise choice. Remember, choosing high-quality organic fertilizer equipment can not only improve production efficiency, but also ensure the quality of fertilizer and the sustainability of agricultural production.