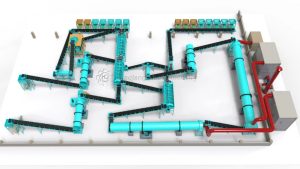

An NPK fertilizer production line is a complete system encompassing “raw material processing – batching and mixing – granulation and drying – coating and cooling – finished product inspection – warehousing.” It involves multiple core pieces of equipment. Mastering the entire process and the key operation points of each piece of equipment is crucial for ensuring the stable and efficient operation of the production line and producing high-quality NPK fertilizer.

Complete NPK Fertilizer Production Line Process: Raw Material Processing (Screening, Crushing, Drying) → Precise Batching (Electronic Belt Scale + PLC Control) → Mixing and Stirring (Horizontal Mixer) → Granulation (Drum Granulator/High Tower Granulator) → Drying and Cooling (Drum Dryer + Cooler) → Coating (Coating Machine) → Finished Product Screening (Vibrating Screener) → Quality Inspection (Nutrient Testing) → Packaging and Warehousing.

Key operational points for core equipment: First, for the crushing equipment, regularly check the wear of the crusher blades to ensure the particle size is within specifications, and maintain a uniform feeding speed to prevent equipment blockage. Second, for the granulation equipment, control the feed rate, binder dosage, and hot air temperature of the drum granulator; for the high-tower granulator, ensure the nozzles are unobstructed to prevent uneven granulation. Third, for the drying and cooling equipment, control the drying temperature and cooling rate to prevent particle cracking and pulverization. Fourth, for the testing equipment, each batch of finished product must be tested for nitrogen, phosphorus, and potassium content using a nutrient analyzer; unqualified products must be returned for reprocessing.

In addition, daily operation and maintenance of the NPK fertilizer production line are also crucial: Before starting each day, check the operating status of each piece of equipment and add lubricating oil; during operation, promptly clean any raw material residue inside the equipment; after shutdown, perform a thorough cleaning and maintenance of the equipment to prevent corrosion and blockage. Proper operation of the entire set of equipment and good daily maintenance can ensure that the NPK fertilizer production line can operate continuously for more than 8 hours, with stable production capacity and a finished product qualification rate of over 98%.