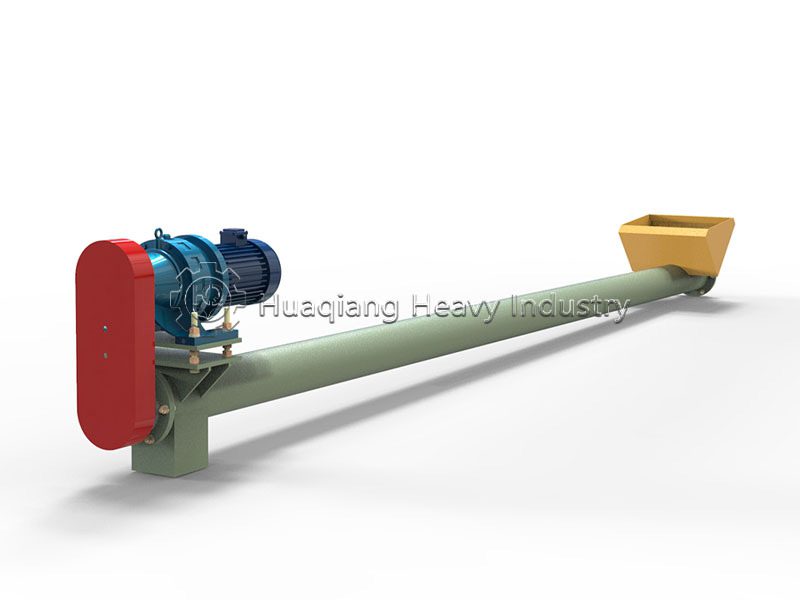

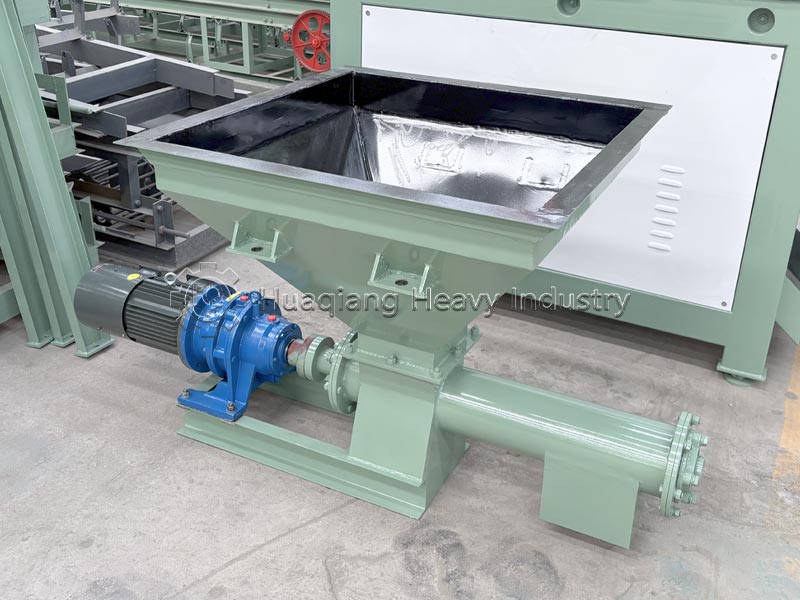

Screw Conveyor

Screw feeders with scraper conveyors and bucket conveyors are equivalent to conveyors. The utility model has the advantages of high transmission efficiency, safe and reliable work, simple structure, complete function, good sealing performance, low noise

DETAILS

Intorduction

Screw feeders with scraper conveyors and bucket conveyors are equivalent to conveyors. The utility model has the advantages of high transmission efficiency, safe and reliable work, simple structure, complete function, good sealing performance, low noise and beautiful appearance. It is widely used in various industrial sectors such as building materials, power, chemical, metallurgy, coal, aluminum-magnesium, machinery, light industry, food, and food industries.

Features

1. The screw conveyor has the characteristics of simple structure, small cross section area, good sealing performance, convenient operation, easy maintenance, and convenient closed transportation.

2. Screw conveyor are widely used in various industrial sectors such as building materials, power, chemical, metallurgy, coal, aluminum-magnesium, machinery, light industry, food, and food industries; it suitable for horizontal or less than 20° dip, powder feeding shape, granular and small pieces of material, such as cement, coal powder, grain, fertilizer, ash, sand, etc., material temperature below 200 °C.

3. Screw conveyor should not transport perishable, highly viscous, easily agglomerated materials.

2. Screw conveyor are widely used in various industrial sectors such as building materials, power, chemical, metallurgy, coal, aluminum-magnesium, machinery, light industry, food, and food industries; it suitable for horizontal or less than 20° dip, powder feeding shape, granular and small pieces of material, such as cement, coal powder, grain, fertilizer, ash, sand, etc., material temperature below 200 °C.

3. Screw conveyor should not transport perishable, highly viscous, easily agglomerated materials.

PARAMETERS

| Model |

Screw Diameter

(mm) |

Rotation Speed

(r/min) |

Capacity

(m³/h) |

| LS160 | 160 | 112 | 9.7-3.2 |

| 90 | 7.8-2.6 | ||

| 71 | 6.2-2.1 | ||

|

56**

|

4.9-1.6 | ||

| LS200 | 200 | 100 | 16.9-5.6 |

| 80 | 13.5-4.5 | ||

| 63 | 10.7-3.6 | ||

|

50**

|

8.5-2.8 | ||

| LS250 | 250 | 90 | 29.9-9.9 |

| 71 | 23.5-7.8 | ||

|

56**

|

18.5-6.2 | ||

|

45**

|

14.9-5.0 | ||

| LS315 | 315 | 80 | 52.9-17.6 |

| 63 | 41.6-13.9 | ||

|

50**

|

33.1-11.0 | ||

|

40**

|

26.4-8.8 | ||

| LS400 | 400 | 71 | 85.3-28.2 |

| 56 | 67.3-22.4 | ||

|

45**

|

54.1-18 | ||

|

36**

|

43.2-14.4 |