Do you know about the process of organic fertilizer production line semi-wet material fertilizer crusher machine?

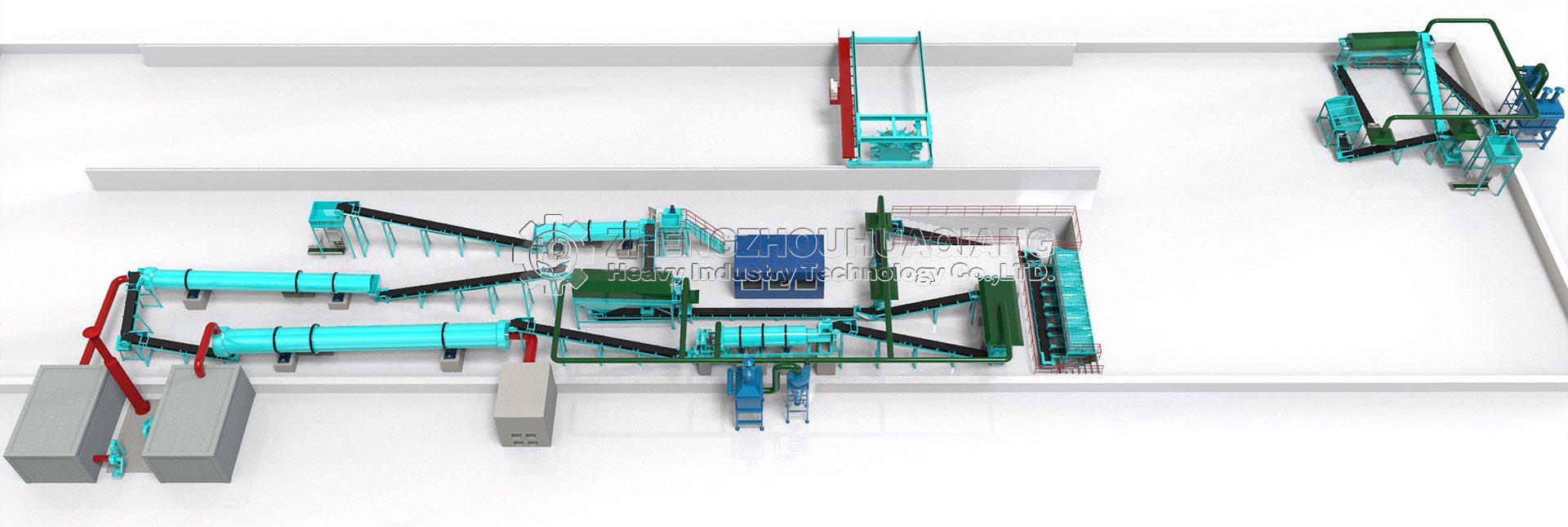

In modern agricultural production, organic fertilizer has been paid attention to because of its ability to improve soil structure and soil fertility. The Organic Fertilizer Production Line is a key link in achieving this goal, and the Compost Crusher is an integral part of the line. This article will introduce the process flow and importance of Compost Crusher in Organic Fertilizer Production Line in detail.

1. Preliminary treatment of Organic Fertilizer Production Line

The first step in the Organic Fertilizer Production Line is the initial treatment of the raw material. This typically includes the collection and sorting of organic waste such as livestock manure, crop stalks, and food industry by-products. After initial screening and decontamination, these materials are transferred to Compost Crusher for further processing.

2. Function of Compost Crusher

Compost Crusher is specially designed for the treatment of organic materials with high water content. It pulverizes the material into smaller particles through a high-speed rotating blade to increase the surface area of the material, thereby improving the efficiency of subsequent fermentation and granulation processes. Compost Crusher is characterized by its ability to adapt to different material humidity without the need for additional drying of the material.

3. Material treatment after crushing

After the Compost Crusher, the material is usually sent to a fertilizer Mixer (such as the Double Shafts Paddles Mixer) for mixing and mixing. This step is to ensure the uniformity of the material and to lay a good foundation for the subsequent fermentation and granulation process.

4. Fermentation and granulation

The well-mixed material then enters the fermentation stage, where it is converted into a stable organic fertilizer. The fermented material enters the Fertilizer Granulating Production Line and is fed through a Granulator, such as Rotary Drum Granulator, to form a granular fertilizer. This process not only improves the physical properties of the fertilizer, but also facilitates storage and application.

5. Drying and cooling

Finally, the newly made granular fertilizer is dried by a Rotary Dryer Machine to reduce the moisture content and prevent fertilizer clumping and mildew. The dried fertilizer particles will be cooled into the Rotary Cooler Machine to ensure the stability of the fertilizer and facilitate subsequent packaging and transportation.

To sum up, Compost Crusher plays a vital role in the Organic Fertilizer Production Line. It not only improves the production efficiency, but also ensures the quality and effect of organic fertilizer. By understanding the process flow of Compost Crusher, we can better understand every link in the organic fertilizer production process, thus providing more efficient and environmentally friendly fertilizers for agricultural production.