Efficient organic fertilizer production: a modern production line with an annual output of 5000 tons

In the green revolution of modern agriculture, organic fertilizers are revered for their positive effects on soil and crop health. With the advancement of technology, the production of organic fertilizers has also ushered in revolutionary changes. In this article, you will find out how to achieve an efficient Production of 5,000 tons per year with a modern Organic Fertilizer Production Line.

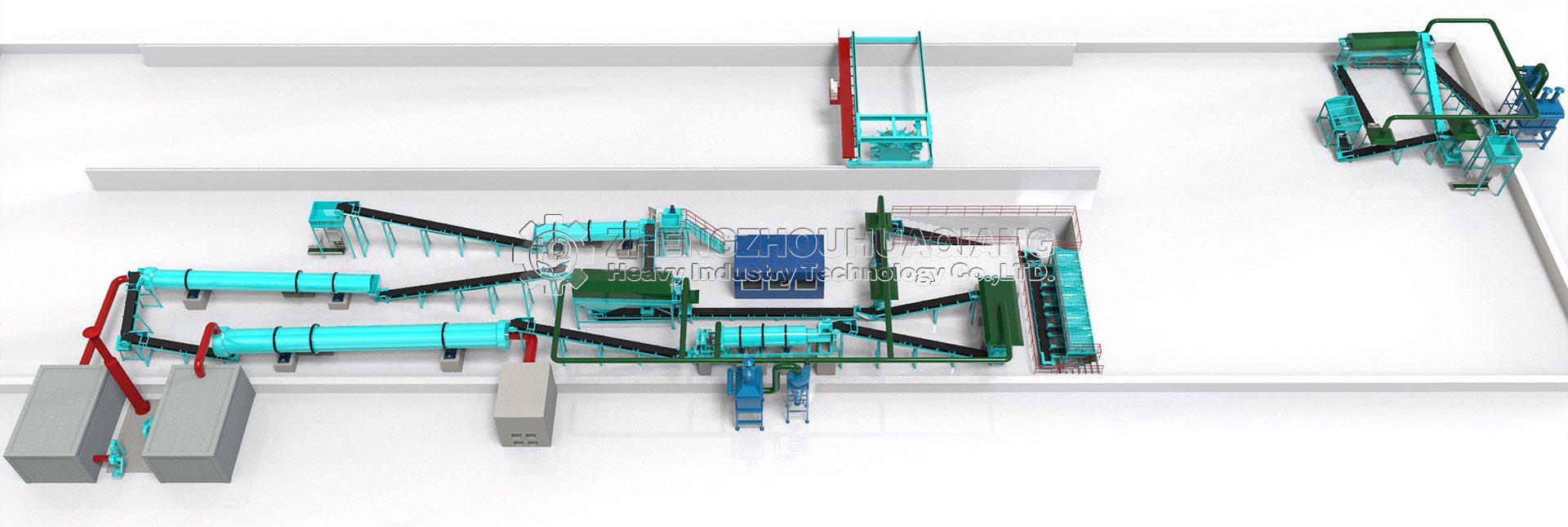

First, let’s introduce today’s main character, the Organic Fertilizer Production Line, through the story of a modern fertilizer factory. In this factory, the production line is highly automated, from the delivery of raw materials to the packaging of finished products, every step is completed by sophisticated mechanical equipment and intelligent control systems. Such a production line not only improves production efficiency, but also ensures the quality and consistency of fertilizers.

Next, we will introduce the key link in the production line – Rotary Drum Granulator. This granulator makes the raw material of organic fertilizer into uniform particles through the rotation of the drum. These particles are not only easy to apply, but also improve the dissolution rate of fertilizer and the absorption efficiency of crops. Rotary Drum Granulator is an important equipment for large-scale production of organic fertilizer.

In the production process, the mixing uniformity of raw materials is the key to ensure the quality of fertilizer. This is where the Horizontal Ribbon Mixer comes into play. It fully mixes various raw materials through a horizontal rotating spiral belt, ensuring the uniform distribution of various nutrients in the fertilizer. The design of this mixer not only improves the mixing efficiency, but also reduces the waste of raw materials.

Finally, we have to mention another key link of the production line – Rotary Dryer Machine. In the production process of organic fertilizers, raw materials often contain high moisture, which is not only conducive to the storage and transportation of fertilizers, but also may affect the effect of fertilizers. The Rotary Dryer Machine evaporates the water in the raw material through hot air to ensure the drying and stability of the fertilizer.

Through the above introduction, we can see that the modern Organic Fertilizer Production Line has achieved an efficient production of 5,000 tons per year through efficient equipment and advanced technology. This not only improves the efficiency of agricultural production, but also contributes to the sustainable development of agriculture. With the increasing attention to environmental protection and soil health, the market demand for organic fertilizers will continue to grow, and efficient and environmentally friendly production technology will become the core competitiveness of the industry.

In the future, we have reason to believe that with the continuous progress and innovation of technology, the production of organic fertilizer will become more efficient and environmentally friendly, providing strong support for the sustainable development of global agriculture.