How do I build 8 ton per hour of NPK compound fertilizer production line?

With the increasing demand for efficient fertilizers in modern agriculture, the construction of 8 tons per hour NPK Fertilizer Production Line has become the goal of many fertilizer producers.

1. Raw material preparation and ratio

To build the NPK Fertilizer Production Line at 8 tons per hour, the first step is to ensure an adequate supply and precise ratio of raw materials. The main raw materials of NPK compound fertilizer include urea, ammonium sulfate, mono-ammonium phosphate, diammonium phosphate, potassium chloride and potassium sulfate, etc. These ingredients need to be precisely metered and blended to ensure the nutrient balance of the final product.

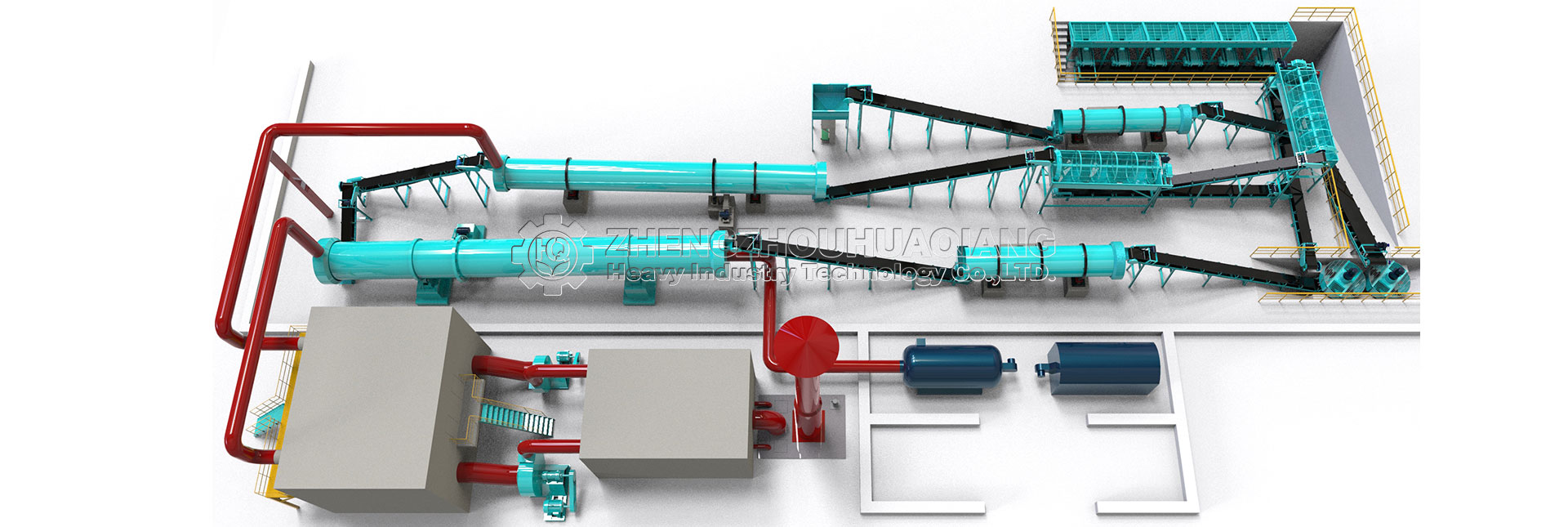

2. Layout of NPK Fertilizer Production Line

NPK Fertilizer Production Line is the core of the entire production process. This production line usually includes raw material storage, metering and mixing, granulation, drying, cooling and packaging. The rational layout of these links can ensure the efficient operation of the production line and the stability of product quality.

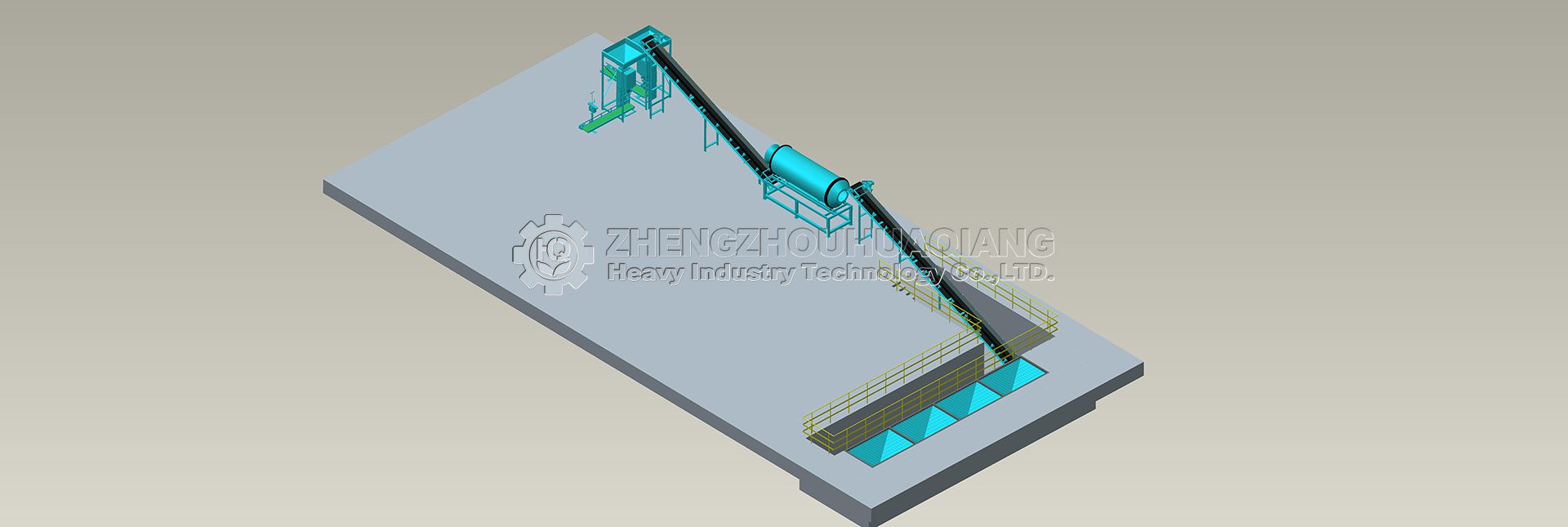

3. Select a Rotary Drum Granulator

Rotary Drum Granulator is one of the commonly used equipment for granulating. It makes the mixed raw materials into granules through a rotating drum. This granulation method is suitable for a variety of raw materials, and can produce uniform and strong fertilizer particles to improve the application effect of fertilizer.

4. Application of Disc Granulator

Disc Granulator is another efficient granulator, which graines the raw material by rotation of the disc and tumbling of the material. This granulator is particularly suitable for the production of large quantities of compound fertilizer particles, which can meet the production demand of 8 tons per hour.

5. Bulk Blending Fertilizer Production Line integration

Bulk Blending Fertilizer Production Line also plays an important role in the production of NPK compound fertilizer. Through high-speed mixing, it ensures that various raw materials are fully uniform during the mixing process, thereby improving the quality and consistency of the final product.

Conclusion

The construction of 8 tons per hour NPK Fertilizer Production Line is a systematic project, involving raw material preparation, equipment selection, process design and many other aspects. By reasonable selection of NPK Fertilizer Production Line, Rotary Drum Granulator, Disc Granulator and Bulk Blending Fertilizer Production Key equipment such as Line can ensure the efficient operation of the production line and the stability of product quality. This can not only meet the demand for efficient fertilizers in modern agriculture, but also bring good economic benefits to enterprises.