How to evaluate the production efficiency and economic benefits of organic fertilizer equipment?

Organic fertilizer is an indispensable part of agricultural production, and the evaluation of its production efficiency and economic benefits is very important for fertilizer manufacturers. From the perspective of science popularization, this paper discusses how to evaluate the production efficiency and economic benefits of organic fertilizer equipment, and draws out relevant keywords.

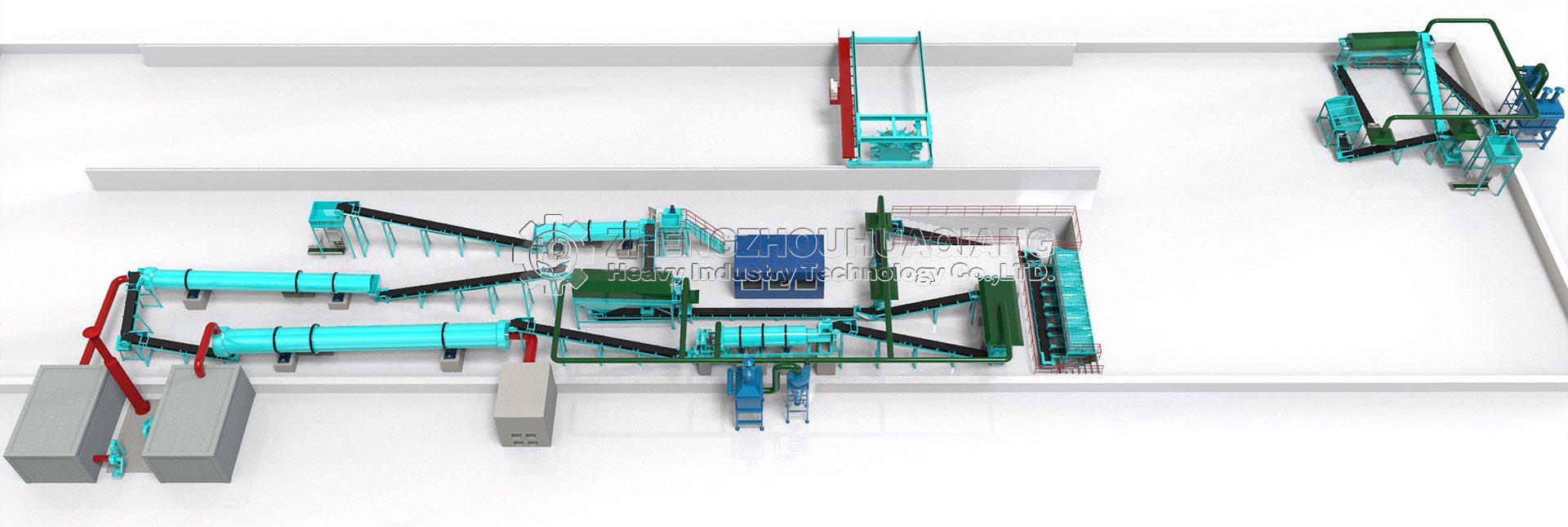

First, we need to understand the basic production process of organic fertilizer. The production of organic fertilizer mainly includes the collection and treatment of raw materials, fermentation, crushing, mixing, granulation, drying, screening and packaging steps. Each step requires corresponding equipment support, and the efficiency of these equipment directly affects the efficiency of the entire production line.

- The selection and configuration of fertilizer production line is the key to improve production efficiency. For example, the Organic Fertilizer Production Line needs to be able to adapt to different raw material characteristics and Production needs, including a variety of Fertilizer Granulating production lines such as rollers, disks, and new organic fertilizers. The automation degree, equipment stability and maintenance cost of the production line are all important indicators to evaluate its production efficiency.

- In the fermentation process, the role of Compost Turning Machine (such as Windrow Compost Turning Machine) is to ensure uniform fermentation and improve fermentation efficiency. The efficiency and effect of the turnover machine directly affect the fermentation quality of organic fertilizer, and then affect the quality of the final product and the production cost.

- Fertilizer granulation Machine series equipment, such as Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine, is the key equipment to make organic fertilizer into pellets. The performance of the granulator directly affects the molding rate and uniformity of the particles, and then affects the market competitiveness of the product.

- Fertilizer mixers, such as the Horizontal Ribbon Mixer and the Double Shafts Paddles Mixer, are used to mix different ingredients to ensure an even nutrient composition of organic fertilizers. The mixing efficiency and uniformity of the mixer are important links to ensure product quality.

- Fertilizer Screening machines, including Rotary Screening Machine and Vibration Screening Machine, are used to separate fertilizer particles of different sizes to improve product uniformity and market competitiveness.

- Fertilizer drying and cooling Machine machinery, such as Rotary Dryer Machine and Rotary Cooler Machine, is used to control the moisture content of fertilizer, prevent caking and improve storage stability.

- Other supporting equipment, such as Uniform Feeder, ensures the continuity and uniformity of raw material supply, which is essential to improve the overall efficiency of the production line.

When evaluating the production efficiency of organic fertilizer equipment, we need to consider the production capacity, energy consumption, ease of operation, maintenance costs and environmental impact of the equipment. The evaluation of economic benefits needs to consider the investment cost of equipment, operating costs, product prices and market demand and other factors.

By taking the above factors into consideration, we can conduct a comprehensive evaluation of the production efficiency and economic benefits of organic fertilizer equipment. This not only helps to improve production efficiency and reduce costs, but also improves the market competitiveness of products and ultimately achieves sustainable economic benefits.