What are the characteristics of organic fertilizer drum granulation equipment?

Organic fertilizer is an indispensable part of modern agriculture, and its production process is highly efficient and environmentally friendly. Drum granulation equipment plays an important role in the Organic Fertilizer Production Line, and its unique design and function bring significant advantages to the production of organic fertilizers.

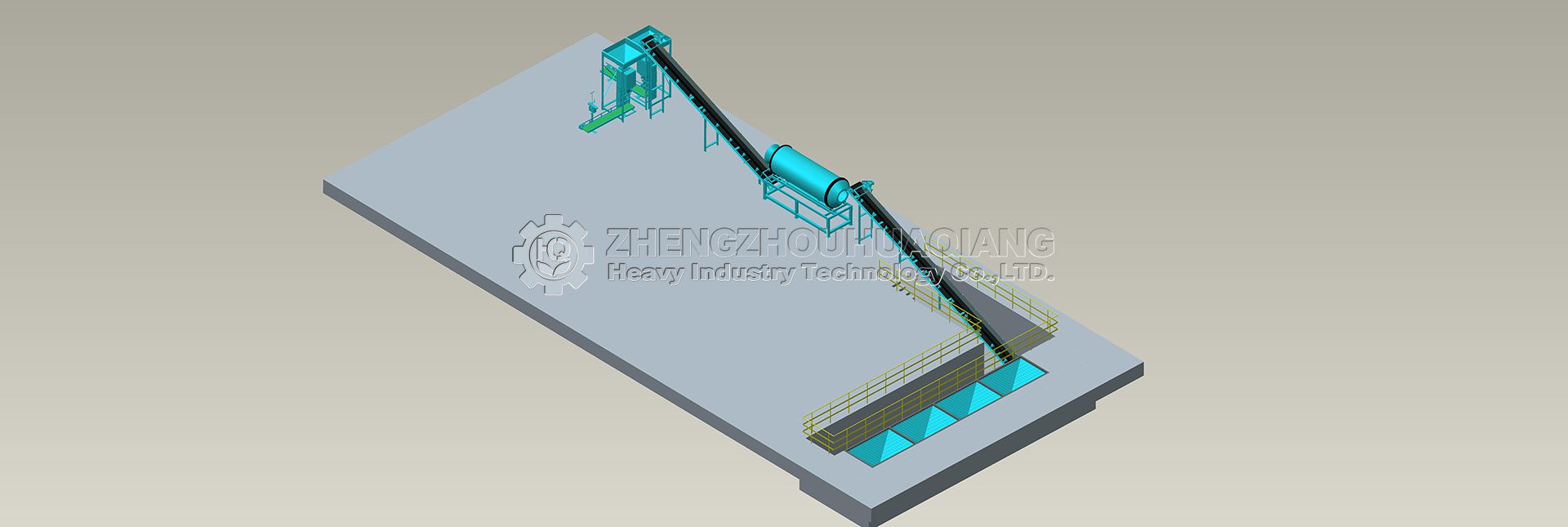

1. Rotary Drum Granulator

Rotary Drum Granulator is one of the core equipment in Organic Fertilizer Production Line. The principle of rotary drum granulator is to continuously roll materials by rotating drum, and aggregate materials into particles through friction and extrusion. This equipment is particularly suitable for the treatment of organic fertilizers with high water content and can achieve efficient granulation in a short time.

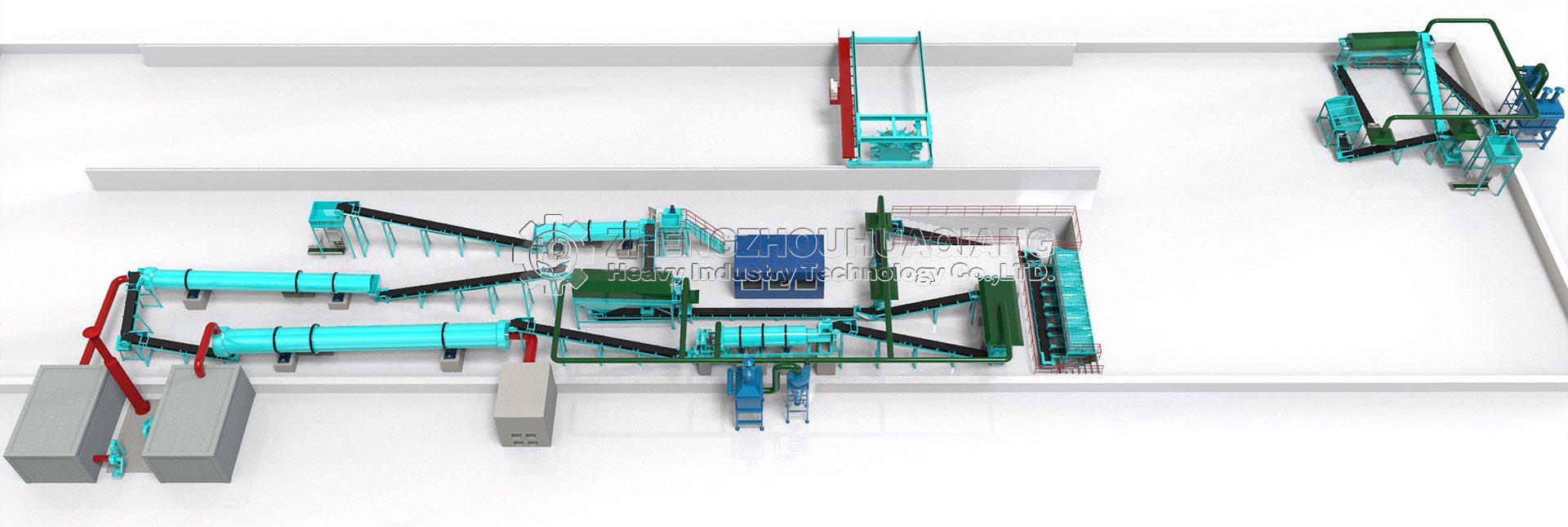

2. Organic Fertilizer Production Line

The Organic Fertilizer Production Line covers the whole process from the pretreatment of raw materials to the packaging of the final product. Rotary Drum Granulator plays a vital role in this production line, being able to convert pre-treated and mixed organic fertilizers into pellets suitable for application. The high efficiency of this production line not only improves the production efficiency, but also ensures the uniformity and quality of the fertilizer.

3. Bulk Blending Fertilizer Production Line

In some cases, organic fertilizers need to be mixed with inorganic fertilizers to provide a more complete nutrition. The Bulk Blending Fertilizer Production Line plays an important role in this process by ensuring that the various fertilizer ingredients are evenly mixed. Rotary Drum Granulator can further process the mixed material into pellets, improving fertilizer application efficiency and crop absorption.

4. Windrow Compost Turning Machine

In the early treatment of organic fertilizers, raw materials need to be fermented to improve their nutritional value and safety. The Windrow Compost Turning Machine plays a key role in this process, ensuring that the material is adequately turned and ventilated during fermentation to speed up the fermentation process. The fermented material is granulated through a Rotary Drum Granulator to form the final organic fertilizer particles.

The organic fertilizer drum granulation equipment is characterized by its efficient granulation capacity, good adaptability and environmental friendliness. These devices can not only improve the production efficiency of fertilizers, but also ensure the quality of fertilizers and the growth effect of crops. With the continuous progress of agricultural technology, the application of drum granulation equipment in organic fertilizer production will be more and more extensive, providing strong support for the development of modern agriculture.