What functions do intelligent control systems in organic fertilizer production equipment usually include?

In modern agriculture, the production of organic fertilizer has been inseparable from the support of intelligent control systems. These systems not only improve production efficiency, but also ensure the consistency and stability of product quality. So, what functions do intelligent control systems in organic fertilizer production equipment usually include?

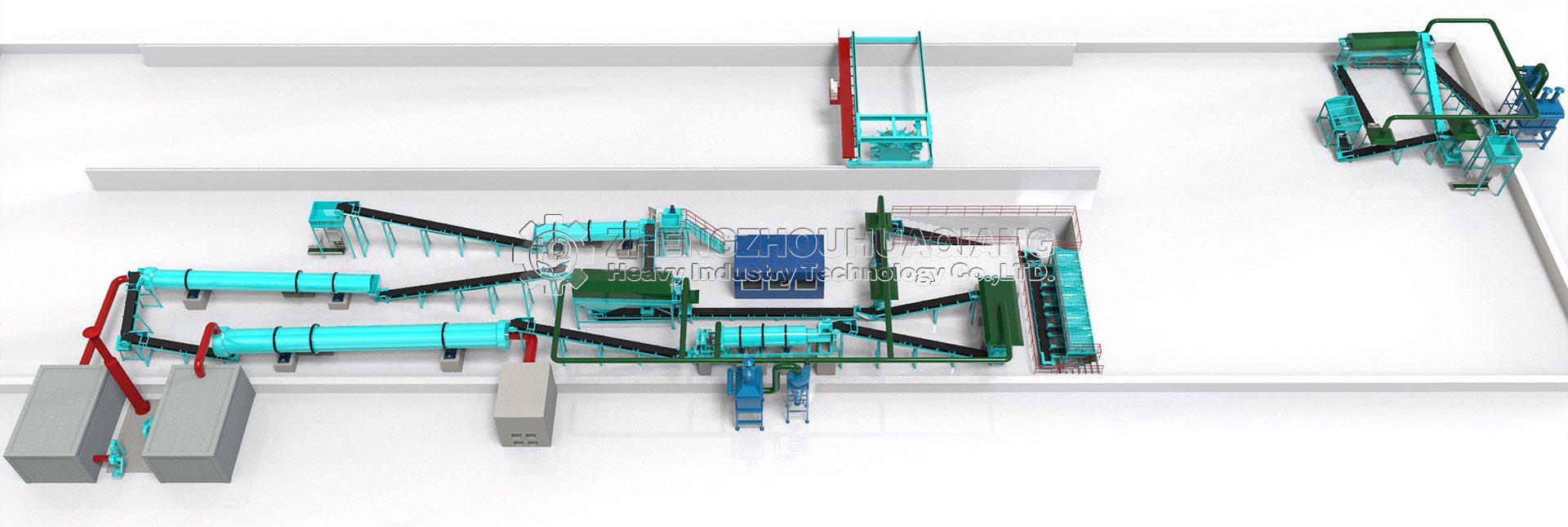

First of all, the intelligent control system can realize the comprehensive monitoring of Organic Fertilizer Production Line. This includes everything from raw material input, mixing, granulation to drying, cooling, packaging and so on.

Taking organic fertilizer Granulator production line as an example, Rotary Drum Granulator, Disc Granulator and other equipment can precisely adjust parameters such as rotational speed, temperature and humidity under the control of an intelligent system, so as to produce organic fertilizer particles that meet the standards. This comprehensive monitoring capability is one of the core values of intelligent control systems in organic fertilizer production.

Secondly, the intelligent control system has automatic batching function. In the production process of organic fertilizer, the ratio of raw materials is very important. The intelligent system can automatically adjust the input ratio of various raw materials according to the preset formula, ensuring that each batch of organic fertilizer has a consistent nutritional composition. This not only improves the production efficiency, but also avoids the error caused by human operation.

In addition, the intelligent control system also has data analysis and fault warning functions. Through real-time monitoring and analysis of various data in the production process, the system can find potential production problems in time and issue early warning signals. For example, when the temperature of the Rotary Dryer Machine is abnormally elevated, the system can immediately issue an alarm to remind the operator to take measures to prevent equipment damage or product quality degradation.

Finally, the intelligent control system can also realize remote monitoring and remote control. This means that operators can view production status, adjust production parameters, or deal with unexpected situations in real time, far from the production site, through terminal devices such as computers or mobile phones. This ability to monitor and control remotely not only increases the flexibility of production management, but also reduces labor costs.

In summary, the intelligent control system in the organic fertilizer production equipment has the functions of comprehensive monitoring, automatic batching, data analysis and fault warning, as well as remote monitoring and control. These functions not only improve the production efficiency and product quality of organic fertilizer, but also reduce the production cost and management difficulty. With the continuous advancement of agricultural modernization, the application of intelligent control system in organic fertilizer production will be more and more extensive.