Fertilizer production equipment maintenance: Expert tips for extending equipment life

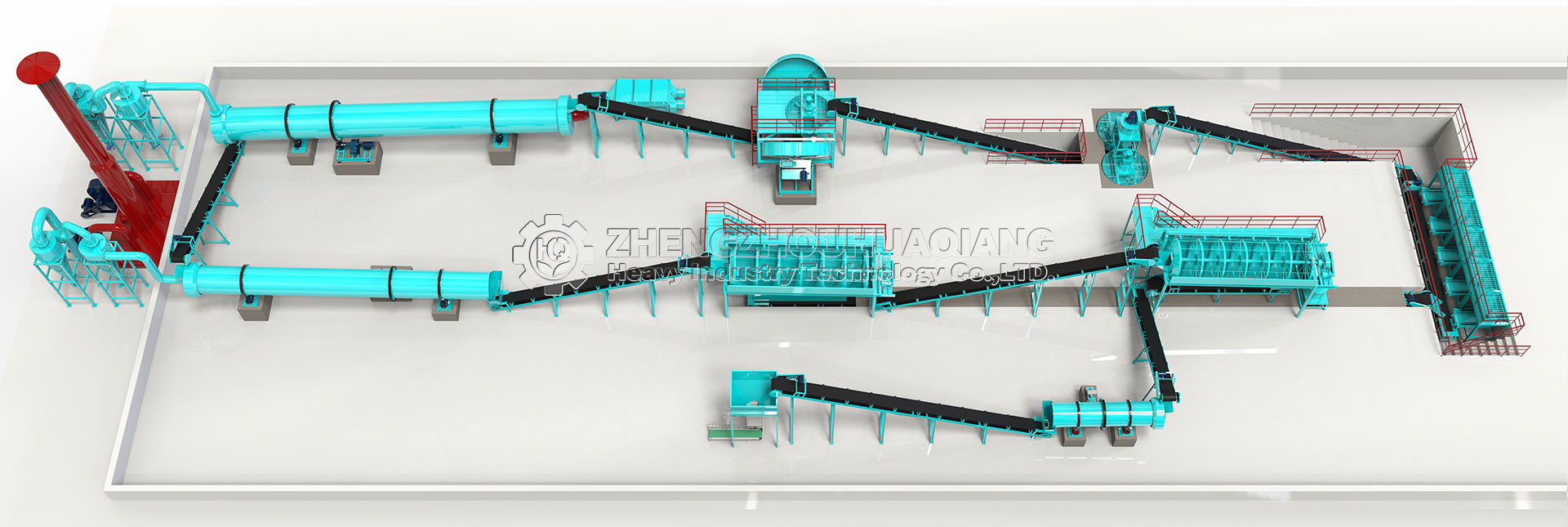

In the big stage of fertilizer production, equipment is like those who quietly pay behind the scenes heroes. They work day after day to ensure the quality and yield of the fertilizer. But like all heroes, they need care and maintenance. This article will explore how to extend the Fertilizer Production Line, Fertilizer Granulating Machine Series, Fertilizer Crusher and fertilizer drying through careful maintenance. The life of Rotary Dryer and Cooler Machine.

First, let’s start with the maintenance of the Fertilizer Production Line. It’s like having a car serviced regularly to ensure its performance is always at its best. The maintenance of the production line is not only to replace the worn parts, but more importantly to carry out regular inspection and cleaning. This prevents breakdowns and reduces downtime, thereby increasing productivity.

Next, let’s talk about the maintenance of the fertilizer granulator series. These machines are a key link in fertilizer production, converting raw materials into pellets suitable for application. Maintaining these machines, like caring for an artist’s brushes, requires care and expertise. For example, Rotary Drum granulators need to check their internal wear regularly to ensure the quality and efficiency of granulation.

In Fertilizer production, the maintenance of Fertilizer Crusher is equally important. They are responsible for crushing raw materials into fine particles suitable for processing. Just like maintaining a sharp knife, the knife needs to be sharpened regularly to keep it sharp. Cage Crusher and Chain Crusher need to check their internal wear and fasteners regularly to ensure the crushing effect and the stability of the machine.

Finally, we will discuss the maintenance of fertilizer drying and cooling machines. These devices are responsible for drying and cooling wet fertilizers for easy storage and transportation. Their maintenance is like taking care of a greenhouse, ensuring the right temperature and humidity. Rotary Dryer machines and Rotary Cooler machines need regular cleaning and inspection to prevent clogging and overheating and ensure long-term stable operation of the equipment.

Through the above introduction, we can see that the maintenance of fertilizer production equipment is a systematic project, which requires us to treat these machines like life. Through scientific maintenance methods and regular inspections, we can ensure the long-term stable operation of equipment, thereby improving production efficiency and product quality. This is not only a respect for the equipment, but also a contribution to agricultural production.