Installation, commissioning and operation maintenance of Compost Crusher in fertilizer production line

In modern Fertilizer Production, Compost Crusher is a key equipment in Organic Fertilizer Production Line, and its installation, debugging, operation and maintenance are directly related to the quality and production efficiency of fertilizer products.

The importance of Compost Crusher in fertilizer production

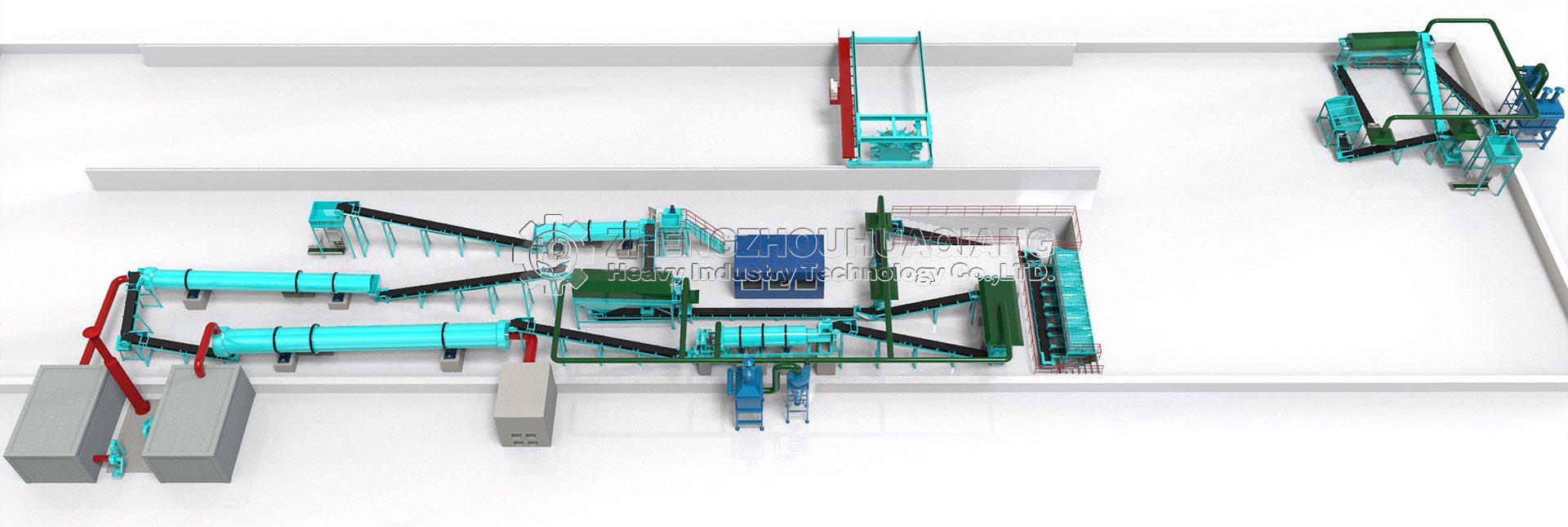

Compost Crusher plays an important role in refining and homogenizing raw materials in the production process of organic fertilizers and blended fertilizers. Whether it is composting from agricultural waste, or raw material pretreatment of nitrogen, phosphorus and potassium composite fertilizer, it is inseparable from the efficient operation of this equipment. By crushing, the surface area of the raw material is increased, which facilitates subsequent mixing, granulation (e.g. using Rotary Drum Granulator or Disc Granulator), and drying and cooling processes, thereby improving the overall production line efficiency and product quality.

Detailed description of installation and commissioning procedures

Foundation preparation: Ensure that the equipment is installed on a solid level concrete foundation and firmly fixed with anchor bolts to prevent vibration from affecting the accuracy during operation.

Vertical correction: During the installation process, special attention is paid to the perpendicularity of the main body of the equipment and the horizontal plane, which is the basis for ensuring the crushing effect and the life of the equipment.

Fastening check: After the installation is complete, comprehensively check whether the bolts in each part are loose, and tighten them one by one to prevent falling off during operation.

Electrical configuration: According to the power requirements of the equipment, reasonably configure the power cord and control switch to ensure the safety and reliability of the electrical system.

Empty load test: After confirmation, empty load test is carried out to observe whether the equipment is running smoothly, no noise, vibration and other abnormal conditions before it can be put into production.

Operation precautions and maintenance

Regular lubrication: the bearing is the heart of the equipment, which needs to be lubricated once per shift, and regularly replace the new lubricating oil to ensure the good operation of the bearing. When replacing, thoroughly clean the bearing and fill it with clean and well-sealed lubricating oil.

Fastening check: The newly installed tire is easy to loose, and it should be checked and fastened frequently to prevent accidents caused by falling off during operation.

Monitoring operation: During the production process, pay close attention to the working status of various parts of the machine, and immediately stop the machine for inspection if any abnormality is found.

Wear parts replacement: regularly check the wear degree of easily worn parts, such as blades, screens, etc., timely replacement to maintain the crushing effect.

Temperature monitoring: Abnormal rise in bearing oil temperature is an important signal of equipment failure, once found should immediately stop to check the cause, eliminate hidden dangers.

To sum up, Compost Crusher as a key link in the fertilizer production line, its installation, commissioning, operation and maintenance is very important. Through scientific installation steps, rigorous operation specifications and regular maintenance, it can not only improve the performance of the equipment, but also effectively extend the service life of the equipment, providing a strong guarantee for the efficient and stable operation of fertilizer production.