With the increasing modernization of agriculture, organic fertilizer has received more and more popularity. It can improve soil, increase yield and improve quality. Organic fertilizer production equipment produces organic fertilizer containing nitrogen, phosphorus, potassium, organic matter, amino acids, protein and so on, using fresh chicken, cow dung and pig dung as raw materials, without any chemical composition.

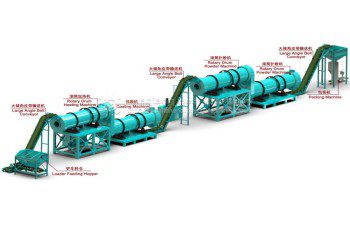

Organic fertilizer production line recycling organic waste make into fertilizer, animal manure, corn straw, wheat straw, soybean straw, rice straw, soybean meal, mushroom residue can be used as raw materials. Organic fertilizer granulation production line including compost turner, crusher machine, mixer machine, granulator machine, screener machine, packing machine, etc.

Video of New type organic fertilizer granulation production line

Raw material of organic fertilizer

Agricultural waste: Straw,dregs of beans,cotton dregs,rice bran,etc.

Animal manure: Mixture of poultry litter and animal waste, slaughterhouse waste, urine and dung of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.

Industrial waste: Wine lees,vinegar residue,manioc waste,sugar scum,furfural residue,etc

Home scrap: Food waste,bones,the roots and leaves of vegetables,etc

Mineral: Humic acid,bentonite,dolomite,etc.

Others: Sludge of the rive,the sewer,etc.

The organic fertilizer production line is mainly divided into three part

Raw Material Compost Process

The turner machine suitable for aerobic fermentation of organic fertilizer, such as livestock and poultry manure, sludge garbage, sugar factory filter mud, straw sawdust. They are necessary compost equipment, this machine adjusts the temperature of the raw material stack. During the operation of the dumper, the raw material aggregates are fully contacted and mixed with the air. A large amount of fresh air can be conserved in the dumper, which helps the aerobic microorganisms to actively produce fermentation heat and raise the heap temperature. When the temperature is high, the fresh air supplement can make the heap temperature drop. A state of alternation of medium temperature, high temperature, medium temperature and high temperature was formed, and various beneficial microorganisms grew and propagated rapidly in the temperature range they adapted. The compost turner machine is high efficiency, smooth operation, strong and durable, even turning throw.

Crushing Machines Part

1.Loader Feeding Hopper

Loader feeding hopper, also called forklift silo, it’s mainly used for conveying materials of loading powder materials, other organic and inorganic raw materials in fertilizer industry. It also has the function of breaking and mixing loose bulk material.This hopper is suitable for the uniform feeding of the crusher in the fertilizer production.

The machine is mainly used to crush materials of biological fermentation organic fertilizer with moisture of 25%~50%. Crushing granule size meets the requirements of granulation, and also adjusted based on user need within a certain range. Have good effect on grinding the glass brick, ceramics and broken stone such kinds of hard matter from the city life garbage organic fertilizer. This machine could reduce equipment investment and save operating cost, which is an ideal choose for machinery.

3.Rotary Screening Machine

For primary screening, the screen machine is to screen the un-fermentation material and let the un-fermentation material fermentation again. The screening machine is common equipment in fertilizer production, mainly used for separating the returned materials and finished product, also realize the classification of the end products, and even classify the end products.

4.Belt Conveyor

Transport the materials continuously, can be used for horizontal transportation or inclined transportation. Belt conveyor is widely used in metallurgy, mine, coal, port, transportation, water and electricity, chemical and other departments to carry on, loading, reloading or accumulating all kinds of normal temperature, loose density of various kinds of bulk. Due to the large amount of transportation, simple structure, convenient maintenance, low cost and strong generality. It can be transported by a single or multiple unit to transport the material, which can be arranged in a horizontal or sloping form according to the technical requirements.

Granulating Machines Part

1.Loader Feeding Hopper

This crusher machine is suitable for crushing bulk materials in compound fertilizer production and after sieving big granules in organic fertilizer production. It is also widely used in chemical industry, building materials, mining and other industries. The chain crusher is fully broken, difficult to stick wall, easy to clean.

The mixer machine stir material in batches, material can be fully mixed. High mixing rate, less residual suitable for feed, concentrated feed, premix additives mixing. It is our new generation hybrid devices.

4.Feeding Machine

Uniform Feeder Machine is a new type of feeder. It is an important equipment for feeding system of fertilizer granulation machine. It is suitable for feeding organic fertilizer and compound fertilizer powder material.

5.New Type Organic Fertilizer GranulatorThe organic fertilizer granulator is used for making granulation of organic matter after fermentation, is the newest technology products by our years of research experience. After fermentation organics don’t need to dry, moisture of the raw material could be in 20%-40%. It process fertilizer powder into granules, the organic content can be high to 100%, make pure organic granulate. Organic material particles can grow up under a certain force, no need to add binder when granulating.

6.Ball Shaping Machine

The polishing machine makes particle roll into ball, form the shape we need. It is the ideal organic fertilizer ball granule device, final products produced more uniform. Large capacity , could working with one set or several sets fertilizer pelletizer at the same time, is flexible.

After granulating, the fertilizer moisture is a little high, it’s not suitable for long-term storage. The dryer machine drying the fertilizer particles to a certain temperature. The Angle and distribution of Jan plate of this machine is designed reasonable, and it is reliable in performance. So its high thermal efficiency, uniform drying, cleaning fewer materials, convenient use and maintenance.

Cooling the granule to the normal temperature. Use dryer together can greatly improve the cooling rate, reduce labor intensity and improve the quality, further remove moisture, reduce the grain temperature of fertilizer.

9.Rotary Screening machine

For second screening, there are some non-uniform particles, after sieving get the appropriate granules that we need, the small diameter particle can be screened down for twice processing, the bigger granules go to the crusher machine again.

Filling the bags and sealing. With filling part,conveyor and sewing part. The packing machine using professional all-digital dual-core processing weighing instruments, the operation is simple and easy to understand, it can store a variety of ranges and other data. Dual weighing hoppers can work individually, alternately and simultaneously, it with larger weighing range, faster speed and more accurate measurement accuracy.

11.Gas/Oil Hot Air Stove

In the drying process and the wet granulation process, the hot air stove is a necessary related equipment, which provides the necessary heat source for the drier system. Energy sources include gas, fuel, power generation, etc.

Welcome to contact us, if you need the above organic fertilizer granulation production line equipment.

We provide fertilizer plant design, process improvement, installation, commissioning, formula and a series of comprehensive services, we can design the fertilizer production line according to your site.