When choosing organic fertilizer equipment, we need to consider several factors to ensure that the production line can operate efficiently and economically. The overall design and capacity of the production line is a primary consideration to ensure that the annual output requirements can be met. First, the Organic Fertilizer Production Line should have sufficient production capacity to meet the annual production target of 1,800 tons. This usually means choosing a multifunctional fertilizer granulator that can handle a variety of raw materials and produce a variety of formulated fertilizers. Such devices include Flat-Die Pellet machine and Rotary Drum granulator, which can adapt to different raw materials and product needs.

When choosing these granulators, we must not only consider their production capacity, but also consider their flexibility of operation and ease of maintenance. For example, Flat-Die Pellet machine are favored for their strong adaptability to raw materials and uniform appearance of finished particles, while Rotary Drum granulator are highly regarded for their continuous production capacity and high level of automation. The selection of these equipment should be based on the specific production needs and budget.

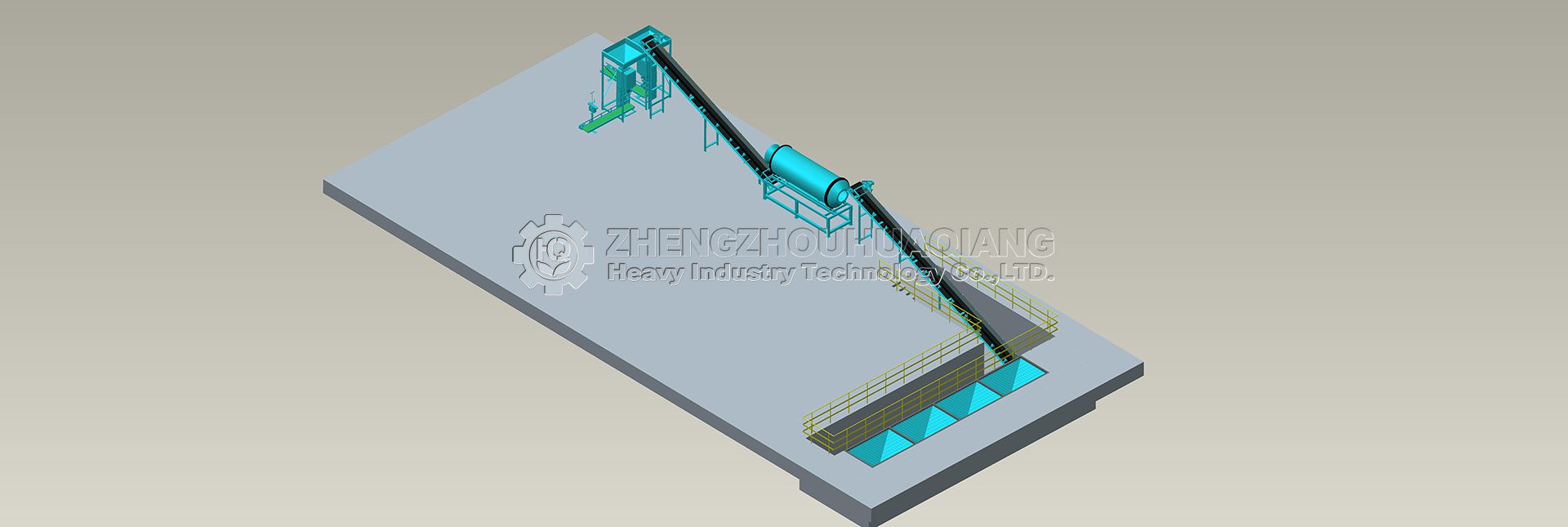

In addition, another key component of the Line is the Bulk Blending Fertilizer Production Line, which ensures an even mix of raw materials, which is essential for the production of high-quality organic fertilizers. When selecting the mixing equipment, its capacity, mixing efficiency and simplicity of operation should be considered. A good mixing system ensures that the various ingredients are fully mixed before granulation, thus improving the nutritional uniformity and effectiveness of the final product.

An excellent annual output of 1800 tons of multifunctional fertilizer pelletizing line should include high-efficiency pelletizing machines and advanced mixing equipment to ensure that the produced organic fertilizer has consistent quality and high yield. At the same time, the maintenance cost, energy efficiency and environmental performance of the equipment should also be considered to achieve long-term economic benefits and environmental sustainability. For example, choosing energy-efficient motors and automated control systems can reduce energy consumption, while adopting low-noise and low-emission designs can help reduce environmental impact.

Before purchasing, it is recommended to conduct detailed market research, compare offers and services from different suppliers, as well as consider the long-term operating costs of the equipment. In addition, good after-sales service and technical support are also factors that cannot be ignored when choosing organic fertilizer equipment. By taking these factors into account, you can ensure that the organic fertilizer equipment that best suits your production needs is selected, so as to achieve efficient, economic and environmentally friendly production goals.