This roller press granulation fertilizer production line not only can make organic fertilizer, but also can produce compound fertilizer. Materials are granulated at room temperature, and there is no drying process, more energy-saving and cost-reducing. Wide adaptability for raw materials, such as fertilizer, feed, chemical industry, and especially good adaptability for rare earth, metallurgy, coal, biological agent, environmental protection project. To some extent, it is the promotion of environmental projects.

Roller press granulation fertilizer production line is often used to manufacture NPK compound fertilizer, such as ammonium choride, ammonium sulphate, ammonium nitrate, diamonium phosphate, potassium Sulphate, magnesium sulfate, magnesium silicate, zinc sulphate, phosphorus pentoxide, etc. The finished granules are very good. And dry powder make granules has lower moisture content.

An annual output 30,000 tons fertilizer is suitable for this 8 tons per hour roller press granulation Fertilizer Production Line, high yield and low consumption, it can produce fertilizer granules in batches and meet economic benefits.

Video of 8 tons per hour roller press granulation Fertilizer Production Line

Features of 8 tons per hour roller press granulation fertilizer production line

1.Simple machine structure

2.Easy operation and maintenance

3.Low power consumption

4.Once forming, no drying process, normal temperature granulating

5.Long service life

6.Raw material moisture is 5%-15%.

7.Suitable for fertilizer, feed, chemical industry.

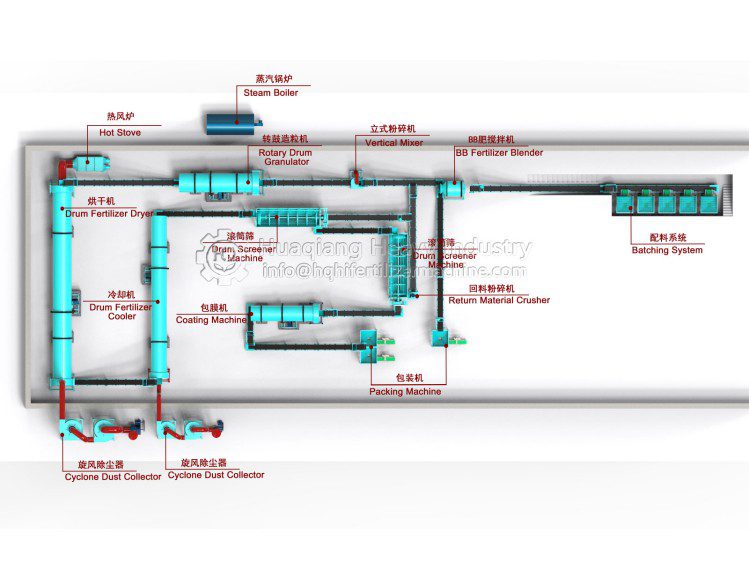

The process of 8 tons per hour roller press granulation fertilizer production line

Batching system

Computer control system with hopper and weighting conveyor. Could weight more than 2 kinds raw materials one time. The batching machine material thickness can be adjusted, accuracy of weighing is +0.5%, control accuracy is+1% Specification. This machine can enhance the accuracy of weighing.

Crush the big material to small powder, and ready to granulate. Chain crusher is suitable for crushing the large material on compound fertilizer production line, and widely used in chemical industry, building materials, mining and other industries.

Could mixing different raw materials completely. The disc mixer machine is mainly used for mixing raw material in batches, material can be fully mixed. The mixer adopts the cycloidal pin gear speed reducer, which has the advantages of compact structure, easy operation, unloading transportation is convenient. We also have other batch mixer and continuous working mixer machine.

Disc feeding machine

The feeding machine is a new type of feeder. It is an important equipment for feeding system of fertilizer granulation machine. It is suitable for feeding organic fertilizer and compound fertilizer powder material.

Double roller press granulator

Double Roller Granulator has compact structure, good stability, good sealing, low noise, easy operation and maintenance, etc. The new machine has won the users praise after coming into the market. Wide adaptability for raw materials, such as fertilizer, feed, chemical industry and especially good adaptability for rare earth, metallurgy, coal, biologics environmental protection. On the other hand, it is also the promotion of environment projects.

It is a common equipment in the production of organic fertilizer and compound fertilizer. In the granules, some granules is large than what you need, and some are small, need separate. Could separate larger granule, small granule,and products one time.

Packing final products in bags, with a storage hopper above the packing machine, with scale could setting weight of bags, contain sewing machine and conveyor. This drum screening machine adopts the integrated screen net which is easy for repair and replacement. This machine is easy to operate and works stable.

Other auxiliary facilities

Belt conveyor

For different capacity, have different size, width 500-1200mm. Length decide by machine and factory layout. elt conveyor is widely used in metallurgy, mine, coal, port, transportation, chemical and other departments, which to carry on, loading, reloading or accumulating all kinds of normal temperature, loose density of various kinds of bulk material.We also have bucket elevator and large angle conveyor.

In summary, roller press granulation fertilizer production line is designed based on mature and advanced technologies, this system can make full use of solar energy, bio-energy and mechanical energy. The whole fertilizer production process is centralized controlled. Hence, our fertilizer equipment features high automation, flexible and convenient operation. Computer controlled batching and packing systems highly guarantee the accuracy of material batching and fertilizer packing.