The disc granulation production line has the advantages of short production process, simple structure, less investment and easy operation, and is more suitable for small and medium-sized enterprises. The raw materials of disc granulator have wide adaptability: urea, ammonium chloride, ammonium sulfate and other nitrogen sources.

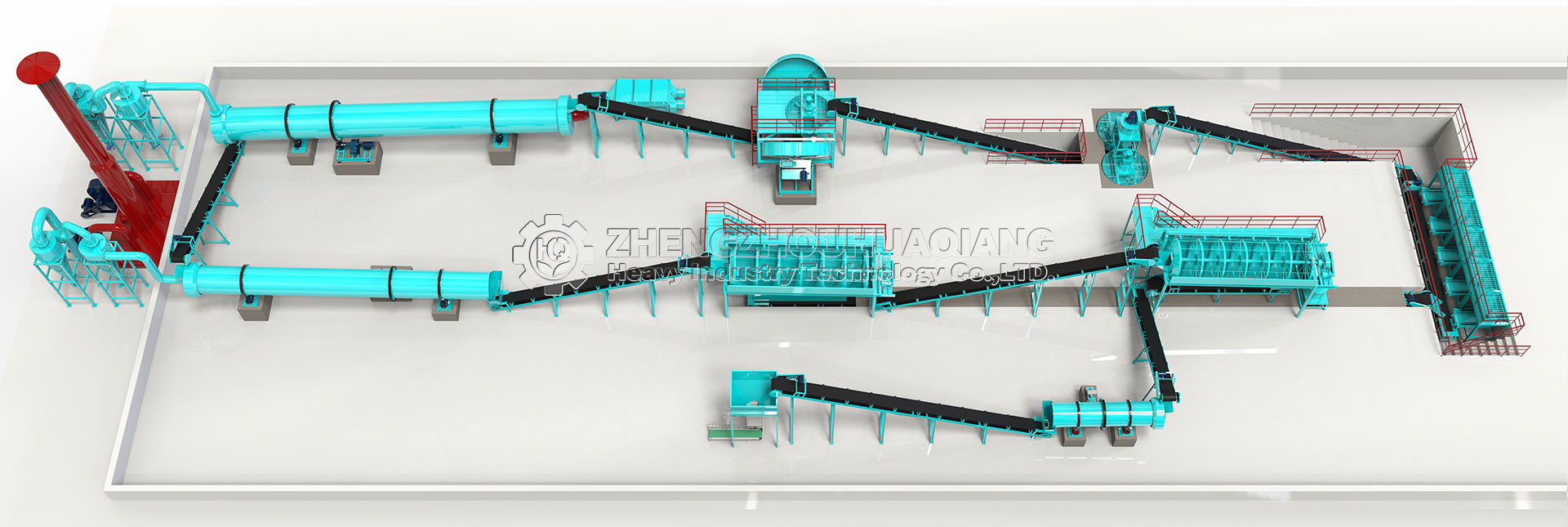

Organic Fertilizer Disc Granulation Production Line

Material: organic fertilizer, compound fertilizer, cement, sludge, pulverized coal.

Motor Power: 1-5t/h

Major Equipment: disc granulator, vertical mixer, chain crusher, rotary screener and so on

Major Equipment

Project Details

The disc granulation production line has the advantages of short production process, simple structure, less investment and easy operation, and is more suitable for small and medium-sized enterprises. The raw materials of disc granulator have wide adaptability: urea, ammonium chloride, ammonium sulfate and other nitrogen sources. Phosphorus sources are: calcium, heavy calcium and so on. Potassium sources include potassium chloride and potassium sulfate. Disc granulation production line can produce a series of inorganic compound fertilizer, organic fertilizer, organic (inorganic) compound fertilizer and biological organic fertilizer with 20-48% nitrogen, phosphorus and potassium nutrients.

Main equipment of organic fertilizer disc granulation production line:

1. Automatic batching system: automatic batching system is mainly composed of feeding system, weighing device, silo and conveyor belt. And the static batching system has both the speed of Dynamic Batching and the accuracy of ordinary static batching (0.2%).

2. Vertical mixer: This mixer has long life, energy saving, small size, fast mixing speed, and can work continuously. It is especially suitable for the use of urban and rural construction projects.

3. Disc granulator: This series of disc granulator is a new type of inclined disc granulator: the granulation rate can reach more than 90%.

4. Dryer: This machine has the characteristics of beautiful appearance, simple operation, low energy consumption, long life, uniform drying and convenient maintenance. It is a more advanced compound fertilizer drying equipment in China. The product is widely used in all parts of the country.

5. Chain crusher: High strength bran-resistant Carbide chain plate with synchronous rotating speed is adopted in the process of grinding. The inlet and outlet ports are designed reasonably, the crushing materials are uniform, the wall is not easy to stick, and it is easy to clean up.

6. Rotary screener: The machine adopts combined screen, which is easy to repair and replace. Its structure is simple, operation is convenient and running is stable. It is an ideal equipment in the production of compound fertilizer.

7. Coating machine: The main engine is lined with polypropylene or acid-resistant stainless steel. According to the technological requirements, the equipment has been specially designed in the internal structure. It is an effective special equipment for compound fertilizer.

8. Packaging machine: Packaging scale mainly consists of automatic quantitative packaging scale (consisting of hopper, feeder, weighing and clamping hopper, kneading mechanism, computer control, pneumatic execution part, etc.) and matching part (conveyor, sewing machine/thermo-closing machine). Using spiral feeding, the material is forcibly discharged by feeding mechanism.

9. Cyclone dust collector: It is mainly used for pre-precipitation of high-concentration dust and separation and recovery of materials. For collecting and separating more than 5-10um coarse particles, the purification rate is high. It has the advantages of simple structure, easy installation, maintenance and management, low cost and operation cost, and small floor area.

10. Conveyor: It is suitable for coal, metallurgy, mining, chemical industry, building materials, wharf, warehouse, construction site and other transportation of bulk materials or bagged goods, especially suitable for use in fertilizer plants, cement plants and other environments requiring manual loading, saving a large number of personnel.

Features:

1) Preferred equipment for organic fertilizer production。

2) The disc pelletizing process uses rolling bonding with large inclination angle to agglomerate into pellets.

3) It can produce any organic raw material particles with strong adaptability.

4) It is the best granulating equipment for sludge, various kinds of feces, wine residue and other hard-to-pellet granules.

5) Multi-segment and multi-angle adjustable disc design makes the particles uniform;

6) Particles can be produced discontinuously and independently.

7) The process is simple, the investment is saved and the effect is quick.

8) General and mature technology, intuitive operation, easier to control.

Project Video

Our Services

Process flow design

We provide you with the pro-phase plan, process flow design and manufacturer equipment according to your special demand.

Sale and Installation

Delivery the machines on time and send technicians to the job-site for guiding the installation and adjustment, training operators and finishing the check and accept.

Plant planning

According to the factory, to make a design about the equipment place, to divide the area of production.

After-sales service

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, spares and the after sale service.