The main raw materials of this organic fertilizer granulation production line are livestock and poultry manure and agricultural waste, which not only creates economic benefits for enterprises, but also makes great contributions to human environmental engineering.

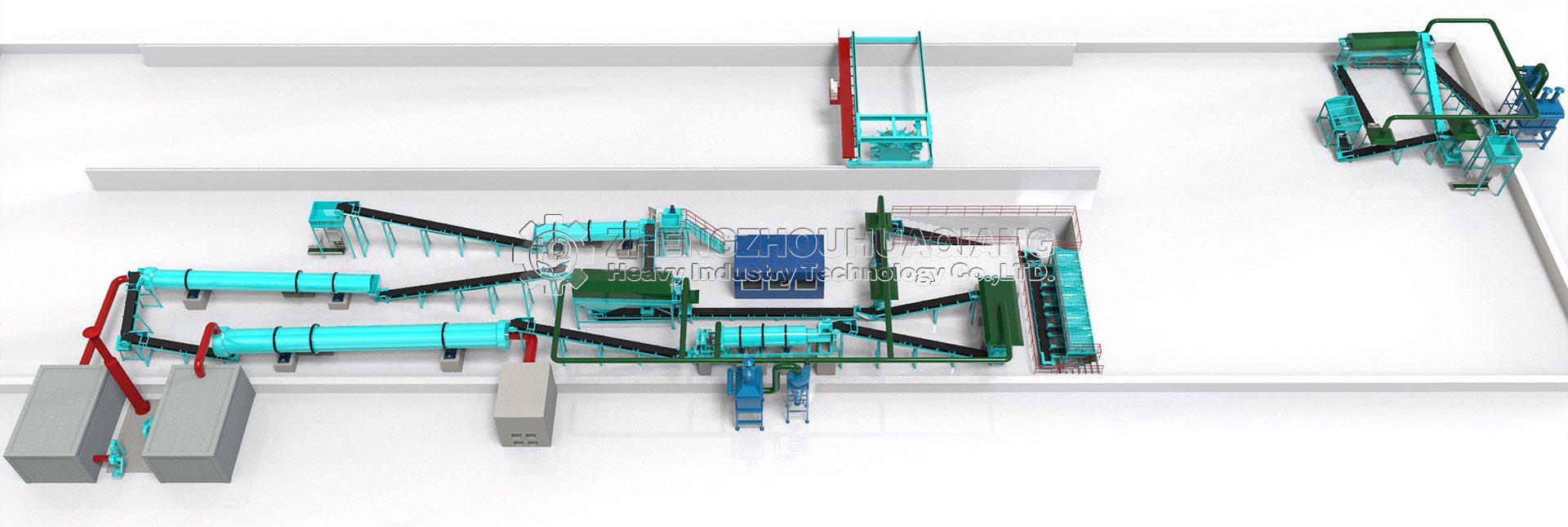

Organic Fertilizer Production Line

Raw materials: Agricultural waste, Manure, Municipal sludge

Motor Power: 2-12t/h

Major Equipment: new type stirring tooth drum granulator, dryer, rotary screener, etc.

Major Equipment

Project Details

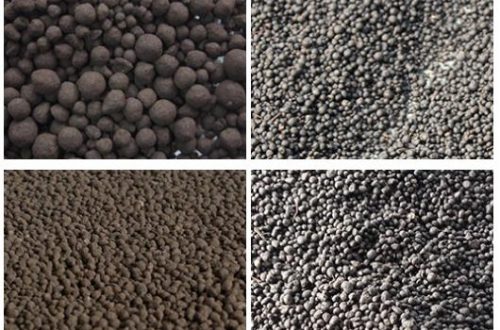

This organic fertilizer production line can also carry on the npk fertilizer granulation, because this organic fertilizer production line uses new type stirring tooth drum granulator.New type stirring tooth-drum granulation production line is often used to process different fermented organic matter into bio-organic fertilizer. One-step forming technology is adopted. The main raw materials of this fertilizer production line are livestock and poultry manure and agricultural waste, which not only creates economic benefits for enterprises, but also makes great contributions to human environmental engineering.

Main equipment of Organic Fertilizer Production Line:

1. Automatic batching system: Automatic batching system is mainly composed of feeding system, weighing device, silo and conveyor belt. And the static batching system has both the speed of Dynamic Batching and the accuracy of ordinary static batching (0.2%).

1. Automatic batching system: Automatic batching system is mainly composed of feeding system, weighing device, silo and conveyor belt. And the static batching system has both the speed of Dynamic Batching and the accuracy of ordinary static batching (0.2%).

2. New type stirring tooth-drum granulator: This series of granulator is a patent product newly developed by our company and Agricultural Machinery Research Institute. It is designed and manufactured by a new wet continuous pusher granulator process.

3. Dryer: This machine is a new generation rotary drum dryer developed by our company’s staff with many years’experience in compound fertilizer production. The machine has the characteristics of beautiful appearance, simple operation, low energy consumption, long service life, uniform drying and convenient maintenance. It is an advanced compound fertilizer drying equipment in China, and the product is widely used in all parts of the country.

4. Rotary screener: This series of drum sieve machine is a common equipment in compound fertilizer production. It is mainly used for separating finished products from returned materials, and can also realize product classification, so that the finished products can be evenly classified. The machine adopts combined screen, which is convenient for maintenance and replacement. Its structure is simple, operation is convenient, and operation is stable. It is an ideal equipment in compound fertilizer production.

5. Cyclone dust collector: Cyclone dust collector is a kind of dust collector, which is mainly used for pre-precipitation of high-concentration dust and separation and recovery of materials. For collecting and separating more than 5-10um coarse particles, the purification rate is high. It has the advantages of simple structure, easy installation, maintenance and management, low cost and operation cost, and small floor area.

6. Conveyor: The working principle of mobile lifting belt conveyor is the same as that of ordinary belt conveyor. It takes belt as the continuous conveying equipment of traction bearing machine. Compared with ordinary belt conveyor, it adds mobile device and lifting device. Because there are more lifting and moving devices, mobile lifting belt conveyor has increased its superior dynamic capacity. It can be based on the site conditions. It is equipped with forklift and other power locomotives to propel or tract the goods to the appropriate place for loading and unloading.

7. Packaging machine: Automatic packaging scale, also known as automatic packaging machine, can be divided into semi-automatic packaging scale and fully automatic packaging scale. The packaging scale mainly consists of automatic quantitative packaging scale (consisting of storage hopper, feeder, weighing and clamping hopper, kneading mechanism, computer control, pneumatic execution part, etc.) and selection part (conveyor, sewing machine/heat closing machine). Using spiral feeding, the material is forcibly discharged by feeding mechanism.

Raw Material:

1. Agricultural waste: straw, rice bran, etc.

2. animal manure: chicken manure, pig, cattle, sheep dung, etc.

3. Industrial waste: distiller’s grains, sugar residue, etc.

4. Domestic garbage: kitchen garbage, vegetable market and slaughterhouse garbage, etc.

5. Municipal sludge: River sludge, sewage sludge, etc.

After safe treatment and fermentation, these raw materials are made into organic fertilizers. Therefore, organic fertilizers contain a variety of organic acids, peptides and rich nutrients, including nitrogen, phosphorus and potassium. It not only provides comprehensive nutrition for crops, but also has a long fertilizer effect. It can increase and renew soil organic matter, promote microbial breeding, and improve soil physical and chemical properties and biological activity.

Features:

Features:

1. The main raw materials of the production line are livestock and poultry manure and agricultural waste. It not only converts waste into treasure, but also protects the environment.

2. The whole process of organic fertilizer production is controlled centrally. The series is highly automated and easy to operate.

3. The proportioning system and packaging system are controlled by computer to ensure the accuracy of material proportioning and fertilizer packaging.

4. The product has high quality, stable performance, compact process layout, advanced technology and convenient maintenance.

Project Video

Our Services

Process flow design

We provide you with the pro-phase plan, process flow design and manufacturer equipment according to your special demand.

Sale and Installation

Delivery the machines on time and send technicians to the job-site for guiding the installation and adjustment, training operators and finishing the check and accept.

Plant planning

According to the factory, to make a design about the equipment place, to divide the area of production.

After-sales service

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, spares and the after sale service.