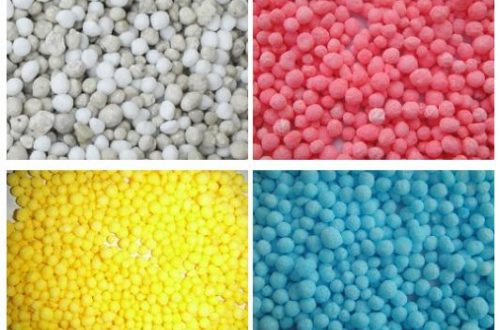

1. The NPK ( Nitrogen, Phosphorus and Potassium) Fertilizer Production Line is our compound fertilizer manufacturing equipment products, they are running stable, the quality of them is high, and they are easy to maintence and repair.

2. The rate of being ball is high, outer recycle materials is few, the comprehensive energy consumption is low, no pollution and strong adaptability.

3.The setting of the whole production line is reasonable and within advanced technology, it could improve production efficiency, reducing the production cost and the production scale could be controlled easily.

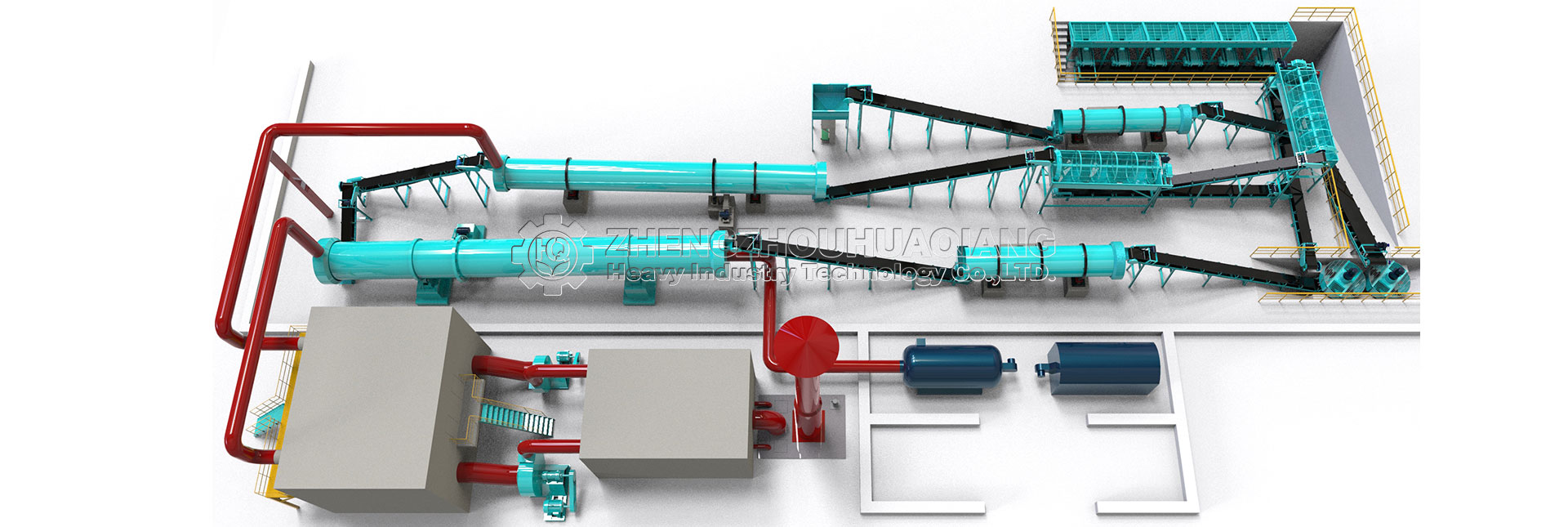

Process Flow of NPK Fertilizer Production Line

Raw Material Batching

Operators strictly add N, P, K, additives and other raw materials into the batching system according to the requirements of each raw material quantity. The raw materials are powdery or granular. No caking phenomenon is allowed in the process of adding raw materials, and the material flow rate should be uniform. Otherwise, it will affect the metering accuracy and the control of granulation process, and ultimately affect the product content. The measured material flows into the crusher and enters the crushing stage.

Crushing

The metered raw material flows into the feed port of the crusher, and the crusher crushes the material to achieve the fineness required for granulation. The crusher not only has the function of crushing, but also has the function of re-mixing. The crushed material enters the belt conveyor through the discharge port, and is transported from the belt conveyor to the drum granulator for granulation.

Granulation

The crushed material is conveyed to the rotary drum granulator for granulation. The solid powder that needs to be granulated rises with the help of the rotation of the cylinder and rolls down under the action of gravity. At the same time, according to the amount of raw materials, a certain proportion of binder is added to granulate. The material is wrapped layer by layer on the surface of the granulation nucleus, which is thickened layer by layer and gradually granulated. Under the action of the above forces, the material gradually forms the base core until it reaches the requirement of granulation and enters the dryer.

Drying

The drum dryer adopts the method of cylinder edge transmission, flange connection and direct heat transfer, which is suitable for drying compound fertilizer after granulation.

Cooling

Drum cooler is mainly used for cooling compound fertilizer products after drying. It can directly cool hot granular fertilizer to near normal temperature.

Screening and grinding of large particles

Screening mainly separates fine powder, finished product and large particulate matter. Firstly, the sieving machine separates the fine powder from the semi-finished product, and then separates the large particles. The separated large particles are crushed by a grinder and then enter the return belt together with the separated fine particles, which are returned to the granulator for granulation. The finished product enters the coating machine.

Coating

The outer layer of the granule is coated with a protective film to prevent granule caking and improve the practicability of the compound fertilizer.

Packing

The finished granules are automatically weighed in the packing machine according to the set weighing. The weighed materials enter the seam section through the conveyor, and the seam work is carried out in the finished product warehouse.

Advantages of NPK Fertilizer Production Line:

1. Raw meterials are extremely versatile

2. It has a high balling rate and the survival rate of biological bacteria.

3. It has a short process flow