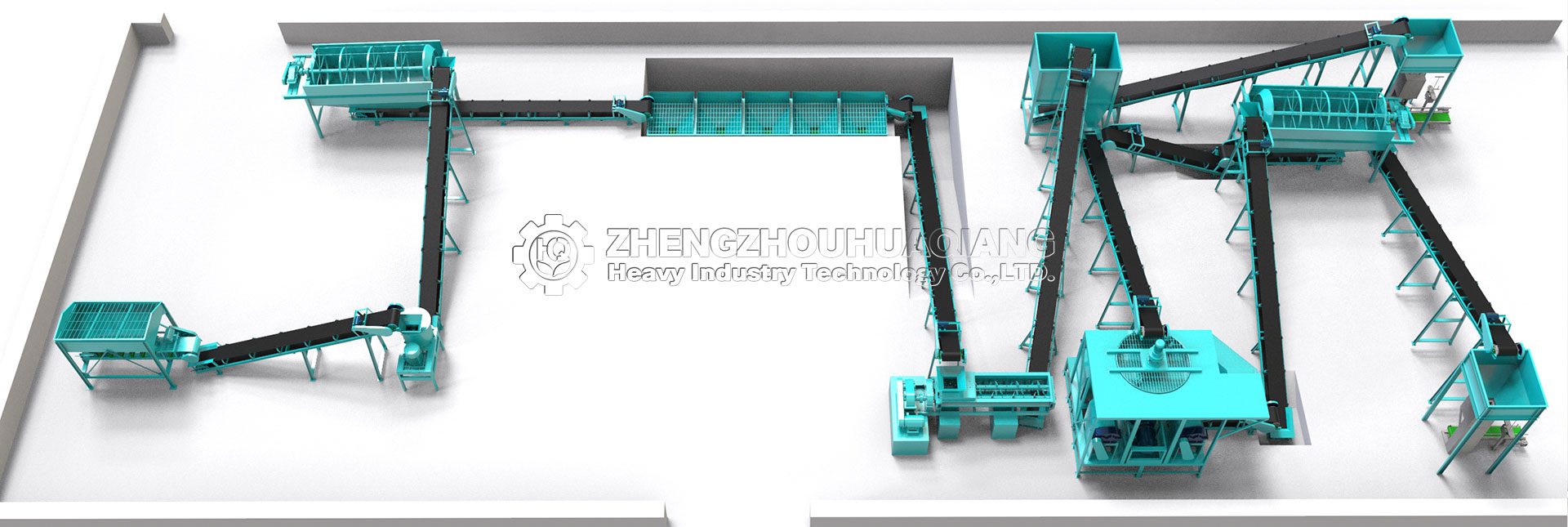

Roller Press Granulator Production Line

Material: Nitrogen, phosphorus, potassium

Motor Power: 1-2.5t/h

Major Equipment: roller press granulator, vertical mixer, batching system, rotary screener and so on.

Major Equipment

Project Details

There are more than 20 kinds of materials which have been successfully used for roller extrusion granulator, and trace elements such as boron, iron, copper, zinc and manganese can be added. Extrusion granulation has no special requirement for the granularity of raw materials. 1-4mm granular materials and fine powder materials are available, unqualified powder materials and powder products are better used, and powder materials are used. Costs can be reduced.

Main equipment of roller press granulator production line:

1. Automatic batching system: automatic batching system is mainly composed of feeding system, weighing device, silo and conveyor belt. And the static batching system has both the speed of Dynamic Batching and the accuracy of ordinary static batching (0.2%).

2. Roller press granulator: This machine is produced by non-drying process, granulating at room temperature and forming at one time. It has the characteristics of less investment and good economic benefit.

3. Vertical mixer: This mixer has long service life, energy saving, small volume, fast mixing speed, and can work continuously. It is especially suitable for urban and rural construction projects.

4. Rotary screener: This machine adopts combined screen, which is easy to repair and replace. Its structure is simple, operation is convenient, and operation is stable. It is an ideal equipment in the production of compound fertilizer.

5. Belt Conveyor: The working principle of mobile lifting belt conveyor is the same as that of ordinary belt conveyor. It takes belt as the continuous conveying equipment of traction bearing machine. Compared with ordinary belt conveyor, it adds mobile devices and lifting devices. Because of the more lifting and moving devices, the mobile lifting belt conveyor has increased its superior dynamic capacity. The site conditions are propelled or towed by forklift and other power locomotives to the appropriate location for loading and unloading.

6. Packaging machine: automatic packaging scale, also known as automatic packaging machine, can be divided into semi-automatic packaging scale and fully automatic packaging scale. The packaging scale mainly consists of automatic quantitative packaging scale (consisting of storage hopper, feeder, weighing and clamping hopper, kneading mechanism, computer control, pneumatic execution part, etc.) and selection part (conveyor, sewing machine/heat closing machine). Using spiral feeding, the material is forcibly discharged by feeding mechanism.

Roller press granulation production:

1. Storage and measurement

Mixed fertilizer raw materials such as urea, ammonium phosphate and potassium chloride are conveyed to the storage bin by bucket elevator and belt. The number of silos, measurement and complexity of mixing technology are related to the number of components in product formulation.

2. Extrusion

The mixed fertilizer mixture is extruded by a roller extruder. The principle is that the material is formed by extrusion. The mixture material is added into the gap between the two rollers by a vertical screw feeder. During the extrusion process, the pressure of the material increases gradually. When the gap between the two axes is very small, the pressure of the material is relatively large, and then decreases gradually until 0.

3. Fragmentation and classification

The plate formed in the counter-roll extruder should be further broken and graded to meet the required particle size. There is a specially designed plate crusher under the counter-roll extruder, where the plate is pre-crushed into several small pieces (sheets). Fine particles on the lowest sieve are recycled into the mixer and extruded. However, the super-large particles retained in the upper layer of the multistage sieve need to be further broken. After crushing, it returns to screening. Correct selection of crushing and screening equipment is very important for the economy of chemical fertilizer extrusion/granulation system.

4. Polishing and dressing

Usually, the final product has to undergo one to two steps of polishing and finishing. Irregular shaped particles are rounded by grinding drum at edges and corners. The fine powder produced in the polishing process is circulated through screening (a layer of screen). In general, anti-caking agent should be added in dressing. The final product of the device is granular fertilizer (1-4mm) in a certain size range.

If a single product of large granular fertilizer, such as granular potassium fertilizer, granular ammonium sulfate or granular ammonium chloride, is produced, the process is simpler and the investment is further reduced due to the elimination of weighing, metering, crushing and mixing of raw materials.